Water-rich Whey: An Invaluable Resource for Beverage Development Toward Sustainable Dairy

Simran Kaur Arora1* and Yash Mali2

1*Assistant Professor, Department of Food Science and Technology, College of Agriculture, G.B.P.U.A.T., Pant Nagar, Uttarakhand, India. Email: sim_n@rediffmail.com

2Research Scholar, Department of Food Science and Technology, College of Agriculture, G.B.P.U.A.T., Pant Nagar, Uttarakhand, India

Submitted: April 6, 2024

Revised: October 29, 2024

Accepted: November 4, 2024

Published: June 20, 2025

doi:10.14294/WATER.2024.4

Abstract

Where there is a scarcity of drinking water in the world, drinkable water is made by purification of available water at a high cost. India will face severe water scarcity by 2050. A major portion (93.5%) of whey, a byproduct obtained during the production of coagulated milk products, is made up of water but due to its sensory properties it is not consumed directly. However, it can be valorized for human consumption by using simple, cost-efficient techniques of manufacturing beverages and soups, whereby its watery portion is utilized as the bulking agent to help meet the daily supplies for liquid intake of an individual. The long-established utilization pattern of whey as concentrates or powders is related to high global warming potential. Similarly, the production and isolation of specific ingredients from whey are technology dependent and generate large quantities of effluents. Whey can be applied to novel uses for producing bioethanol, and electricity (biogas) but, at the cost of nutrients and water. Hence, there is a need to spread awareness among the dairy processors for valorizing whey (as whole) to help quench the thirst of poor people at low-cost. Besides discussing these concerns, the present review advocates the transformation of whey (even acidic whey) into various flavorful beverages or soups as a source of both nutrients and water (zero wastage), thus making positive contributions to ameliorating the problems of poor access to potable water, malnutrition, and pollution of aquatic ecosystems.

Introduction

Whey is a nutritious, low-calorie product with high physiological activity (Beseduik et al., 2024). It contains almost all the components of milk except for casein, fat, and fat-soluble vitamins (Borkar et al., 2020) and poses a threat to environment sustainability when disposed of into drains. The major portion of whey (93.5%) is water, which is largely unexploited. The water present in whey is essentially the part of milk that is left behind after removing the proteins of the milk following coagulation. Since whey is derived from milk, the water content of fresh whey is of the same quality as that of the water present in the coagulated milk product whether it is cheese, paneer or casein. Thus, it can be assumed that fresh whey is as nutritionally, chemically and microbiologically safe for human consumption as that of the edible coagulated products obtained from the same milk under the same set of processing conditions. An adult needs to drink an adequate intake of 2.7 to 3.7 L of potable water/day from various sources (plain water + beverage + food moisture) (EFSA, 2010). In regions where potable drinking water is scarce, these needs may be met by the application of desalination technologies to brackish and sea water. However, such processes are costly and energy intensive. For example, the cost of producing and transporting potable water by the desalination process is reported to be between $1.11 and $2.71/m3 (Dooley, 2014). While the cost of treating wastewater for non-food reuse ranges between $1.21 and $2.17/m3, the cost of obtaining potable drinking water from brackish water falls between $0.77 to $1.49 /m3. Costs for desalination of sea water range between $1.69 to $3.47/m3 (Heather Cooley et al., 2019).

The water consumed by dairy animals is also sometimes concerning. The water footprint for animals largely comes from the crops that dairy animals consume as feed. This is calculated as a weighted total global average water footprint equal to 1020 m3/ton for milk production, 4745 m3/ton for milk powder and 5,984 m3/ton for cheese production, respectively (Mekonnen and Hoekstra, 2012). Besides this, the dairy industry is much criticized for creating pollution through the drainage of whey, and with the use of energy intensive operations such as drying. Under sustainability, scarcity of resources and protection of the environment is of central concern (Kuhlman and Farrington, 2010). Valorization of whey (as whole) into drinks can help mitigate the water footprints caused by dairy herds, to a large extent. It can contribute to sustainable solutions in 3 ways: First, whey will no longer be part of the effluent (zero wastage); second, whey will be utilized completely in beverages and soups without using techniques such as drying; and third, whey will contribute to the water portion of drinks, and may thus offer sustainable solutions by protecting the environment and decreasing the water footprint of the dairy industry.

Whey contains 6.5% total solids, comprising 0.55% protein and 4.9% lactose, suspended in 93.5% water. The global annual whey production is estimated to be between 187 and 206 million tons (MT) in total for 2023, which will increase to 203-241 MT by the year 2030 (Buchanan et al., 2023). So, on average, 93.5% of 222 MT (equal to 207 MT) is water that could be valorized for human use. It is ironic that this massive amount of consumable water is drained off or evaporated to make powders. In both cases, a valuable portion of drinkable water is lost as fluid or as vapor. Beverage companies, like Nestle, suggest that collective efforts are necessary to tackle the problem of scarcity of drinking water. It is crucial that collaborative work be undertaken between the dairy and beverage industries to initiate the conversion of whey into potable beverages (AWS, 2020). Product diversification employing whey as a replacement for water has also been previously suggested (Divya and Archana, 2009). For example, in whey-based tomato soup, whey has been directly utilized up to 80% for the preparation of soup along with the addition of spices, condiments, butter and thickener (Arora, 2022) and in the manufacturing of acid whey fermented beverage with flaxseed gum, more than 94% whey can be utilized (Łopusiewicz et al., 2022). Adoption of such simple methods of whey valorization by manufacturers is one means by which the twin problems of malnutrition and lack of access to clean drinking water can be tackled, at low cost.

Whey Valorization for Water Security

Due to climate change, population growth and human activities, including agriculture, one of the most urgent environmental challenges is the globally sustainable management of water resources (Rodell et al., 2018). An estimated 5 billion people live in areas where threats to water security exist (Vörösmarty et al., 2010) and freshwater resources are continuously declining as per the analysis published in the journal Nature (Rodell et al.. 2018). According to the WHO/UNICEF Joint Monitoring Programme Report (2011) for Water Supply and Sanitation, almost 900 million people worldwide did not have access to clean water then; now the situation is even more worrisome. The UN World Water Report of 2023 estimates that this applies to 2 billion people (roughly 26% of the world’s population). More than 80% of wastewater enters the environment without being treated/reused (WWAP, 2017). Therefore, globally some 2 billion people depend on a drinking water source contaminated with feces, which put them at risk of contracting infections such as cholera, dysentery, typhoid and polio (WHO/UNICEF, 2021). However, new technologies are creating opportunities for recycling and reuse of wastewater (WWAP, 2017), such as using solar energy to harvest drinking water from the air (Lord et al., 2021). It simultaneously produces electricity and freshwater (Wang et al., 2019) and strengthens the water–food–energy system resilience.

Along with high water content, whey contains (Table 3) nearly all the water-soluble vitamins that were originally present in milk (Perasiriyan et al., 2013). If the water is drained as waste, along with the nutrients in the water portion of whey, the opportunity to feed people who do not have access to clean drinking water is lost. In India (the largest producer of milk in the world), large quantities of milk are utilized to produce paneer, chhana, casein, chakka and shrikhand/Greek yoghurt, thus producing enormous quantities of whey (Borkar et al., 2020). It is predicted that India will face severe water scarcity by 2050 (He et al., 2021). Utilization of whey to produce beverages, soft drinks and wines contributes almost all the nutrients of milk except casein and fat, thus making it highly nutritious. Since the production of whey is normally scattered across a region, we recommend that small manufacturers, restaurants, institutional kitchens, and consumers at household levels use whey in beverages or soups that normally require large amount of drinking water for preparation. This will help reduce environmental pollution and global warming.

Challenges in Whey Valorization

Sensory Quality: Whey has an opaque appearance and a dull greenish-yellow color with a slightly acidic taste (Mallik and Kulkarni, 2010). Whey, as such, is unsuitable for human consumption because of its poor taste and thin consistency. Normally it is discarded into drains, as the focus of the dairy producer is on the main product such as cheese/paneer/chakka. When drained, whey places a heavy burden on the environment as it is rich in nutrients and demands high oxygen for its assimilation into nature (Cruz-Salomon et al., 2019).

BOD and COD values: Whey disposal as sewage is uneconomical and is of environmental concern as it is regarded as one of the most polluting food byproduct streams, with a biochemical oxygen demand (BOD) greater than 35,000 ppm and a chemical oxygen demand (COD) greater than 60,000 ppm (Smithers, 2008; Cruz-Salomon et al., 2019). The increased environmental pollution contributes to a vicious cycle of climate change with decreased agricultural production leading to malnutrition and poverty. Therefore, ecologists are rightly concerned about the heavy burden that whey imposes on the environment, while humanitarians feel that whey is a valuable commodity that should be utilized in feeding the world’s hunger (Vyas et al., 1980) and thirst.

Hygienic Handling, Processing and Storage: Whey has as high a water activity as that of milk, and, therefore, to protect it from spoiling, it requires careful handling during storage and transportation. We recommend that whey collection and storage should be done in a hygienically safe facility where there are also some provisions for conducting pasteurization and cooling (below 100C) before storage into clean vessels/silos. When required, it also demands chilled transportation. If the whey is not pasteurized immediately, it must be stored and maintained below 5°C (Hebishy et al, 2023); otherwise, with its nutrients and high water content, the microorganisms present (possibly obtained as a byproduct of cheese/chakka manufacturing or through contamination from the environment/handling) may grow in it, thereby decreasing its overall quality and posing a threat to consumer safety (for more discussion of proper whey collection and storage, see the Discussion with Reviewers section at the end of this review).

Production of Whey Concentrates and Powders: Whey, if not drained, is normally transformed into a variety of valuable products including whey protein concentrates, whey protein isolates, and whey powders, with the application of different energy-intensive techniques, such as membrane concentration and/or fractionation and drying, fermentation or hydrolysis (Djuric et al., 2004). Energy usage has been highlighted as the most significant contributor to global warming potential. Due to the process of evaporation and drying in the manufacture of powder products, the direct energy usage is very high (6.51 kWh kg-1 of milk powder and 8.69 kWh kg-1 of whey powder produced, respectively). When this is compared to total energy use on the dairy farm, the direct energy used in the processing of raw milk into fluid milk (packaged pasteurized milk) is only 0.32 kWh kg-1 (Finnegan et al., 2017). During the normal process of evaporation and drying using evaporators and spray dryers, almost all the water content of whey is lost as vapor to the environment, and thus, in effect, it valorizes only the whey solids. With the application of membrane filtration, such as forward osmosis/reverse osmosis, however, water can be recovered successfully while producing whey concentrates/powder (Aydiner et al., 2013), but it involves high energy usage. Therefore, preparation of whey powders and concentrates are not considered economical and environmentally friendly techniques when compared to the use of whole whey in beverages and soups if made using simple techniques of pasteurization or aseptic packaging as practiced commonly for standardized milk, flavored milk or buttermilk in India.

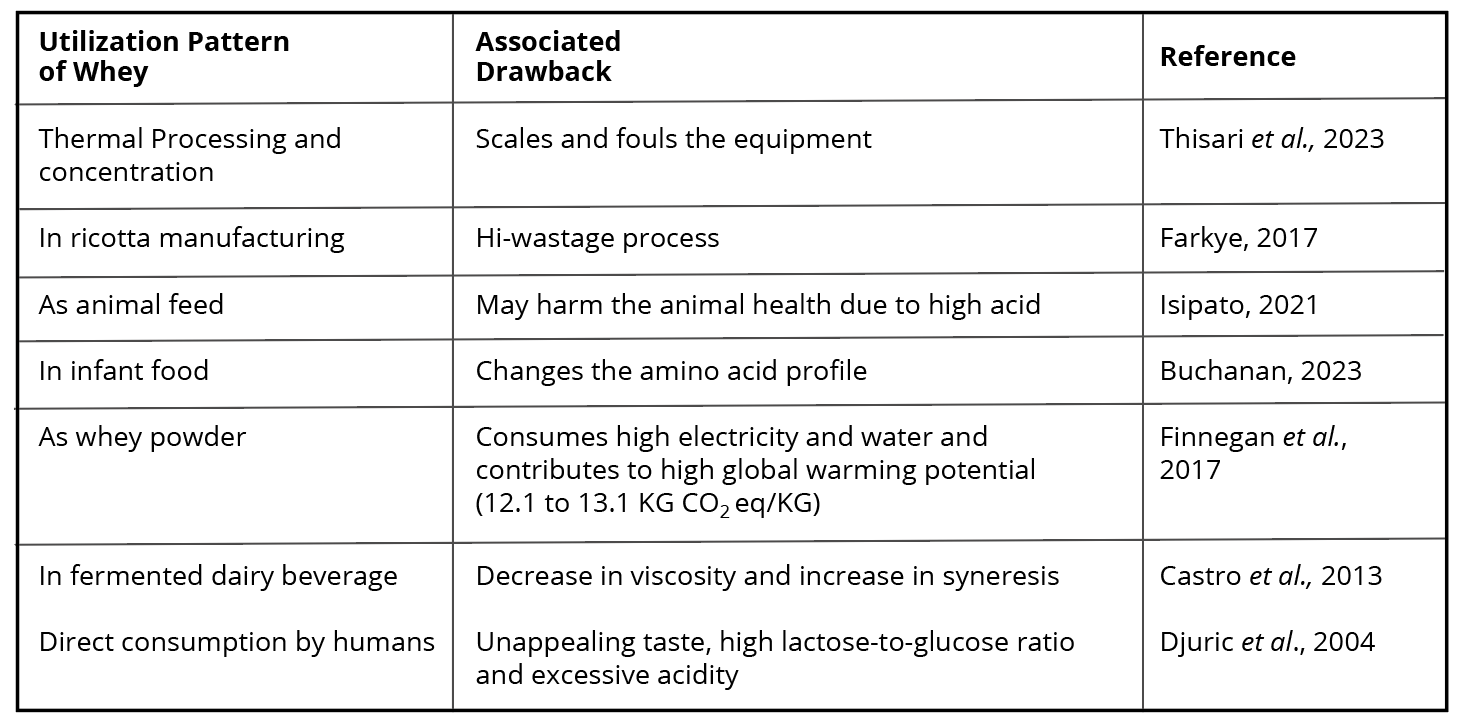

Typical Issues Associated with Acid Whey: Milk protein coagulation, leading to the formation of whey, occurs through the action of acid or proteolytic enzymes (Macwan et al., 2016). There are two main types of whey: acid whey, which is generated during the production of paneer, channa, chakka and acid casein; and rennet whey, produced during cheese manufacturing. Different coagulation methods result in distinct whey types. In general, sweet whey, often derived from cheese manufacturing, has a pH above 5.6, while acid whey, obtained through fermentation or acid addition, has a pH below 5.6 (Tunick, 2008). The obtained whey can be further categorized based on the type of coagulant used, such as lactic acid, citric acid, GDL (glucono delta-lactone) or highly acidic whey from previous lots. Acid whey requires special processing steps, such as neutralization with the help of calcium hydroxide or magnesium hydroxide and the addition of sodium silicate as a free-flowing agent before drying to prepare whey powders (Huffman and de Barros Ferreira 2011). There are several difficulties associated with the reuse of whey (Table 1). Some of the concerns with the reuse of acid whey are:

1. Acid whey as animal feed is not desirable since it can affect animal health.

2. Release on soil: The deposits of organic matter, acids and minerals as salts may negatively affect soil quality.

3. Wastewater treatment dairy ponds: Dairy ponds are economically unsustainable since they produce large amounts of sludge and require high energy to maintain continuous aeration over a long period of time.

4. Electrodialysis or ion exchange treatment may be used to demineralize acid whey but generate a large quantity of wastewater, which creates further disposal problems.

Due to the practical difficulties faced by processors in handling acid whey, it is used to produce alcoholic spirits or to produce biogas, which is a renewable source of energy (Buchanan, 2023). The utilization of whey to produce biogas as a means of producing electricity and running dairy plants using the same electricity may help result in net zero greenhouse gas emissions (Jungbluth et al., 2007). Investment in purchasing anaerobic digesters may help small-scale dairies manage their supply of electricity using whey as a substrate (Gosalvitr et al., 2019). However, the nutrients and water-rich fluid obtained from milk coagulation will be lost to obtain energy. Therefore, different strategies, such as the use of whey for energy production in combination with its use as animal feed and for the reuse of whey to produce cheese (e.g., Ricotta cheese), are sometimes recommended to have net negative impacts (-0.05 kg CO2 eq./kg cheese) on the global warming potential (Gosalvitr et al., 2021).

Whey Valorization into Beverage Manufacture: A Sustainable Solution

Due to the bulkiness of the watery portion of whey, it imparts unique functionality in beverage and soup, which can be easily developed using simple techniques of in-bottle pasteurization (Bhushan et al., 2022; Devi et al., 2017; Arora, 2023). Compared to plain potable water (as an ingredient), whey adds to volume and its total solids provide additional viscosity to the product. Its greenish-yellow color is primarily attributed to the presence of water-soluble and heat-stable riboflavin and it could be used to develop a whey-guava beverage by heating whey at 450C with the addition of guava pulp (25%), sugar (10%), stabilizers such as guar gum (0.05%) and sodium alginate (1%) (Divya and Archana, 2009). The beverage was added with a permitted preservative potassium metabisulfite (100 ppm). The mixture was filtered, bottled, crown-corked, and pasteurized in bottles at 700C for 35 minutes. The beverage was then cooled and stored under refrigeration until use (Divya and Archana, 2009). Similarly, to have acceptable consistency, different concentrations of thickeners (carrageenan, pectin, and starch) were assessed for developing chocolate beverages using whey-dissolved water-soluble soybean extract. The beverages were formulated with whey, 5.5% water-soluble soy extract, 4.5% sucrose, 6.0% chocolate, and 0.1% vanilla extract. The optimal formulation of the stabilizer contained 46% carrageenan and 54% pectin when used at 500 mg per 100 mL (Oliveira et al., 2017).

Diacetyl flavor compounds and lactic acid contribute to its slightly acidic flavor (Mallik and Kulkarni, 2010). With seasonal fruits, a variety of fruit-based whey beverages can be developed. One such preparation is the whey-based custard apple beverages developed with different combinations of whey and custard apple pulp (90:10, 85:15, and 80:20). Among all the combinations, the beverages prepared from 90% whey and 10% pulp demonstrated superior sensorial and physicochemical properties (Ingale et al., 2009). A whey-based banana herbal beverage could also be developed using banana juice (10%), sugar (8%), and Mentha arvensis extract (2%). The whey was heated to 450C, after which other additives were added. After proper mixing, filtration, and bottling, the beverage achieved a shelf life of 15 days at a refrigerated temperature through in-bottle pasteurization in boiling water for 30 minutes (Yadav et al., 2010). While the pH of a beverage is affected by the type of ingredients, particularly the type of fruit, the acidity is adjusted mostly by the application of citric acid. The sweetness of whey beverages is improved by the addition of sucrose or other sweeteners, such as fructose or enzymatically hydrolyzed lactose. Djuric et al., (2004) employed a factorial design to prepare whey beverages using fruits (orange, pear, peach, and apple), citric acid, and sucrose. A peach-whey blend containing 6% dry matter, 2% sucrose, and adjusted acidity with citric acid to achieve a pH between 3.75 and 3.60 was identified as the most acceptable formulation.

Mango drinks are popular in India. Whey is advocated to be used in creating low-cost beverages with high popularity and nutritional benefits (Kanchana et al., 2021). Therefore, one such whey beverage was developed with mango pulp (12%), sugar (8%), water (48%), and paneer whey (32%) and lemon grass distillate (0 to 2.5%). The beverage containing 1.5% lemongrass distillate was found to be acceptable, achieving an average sensory score of 8.33 after 60 days of storage. It exhibited properties such as 14.93°B TSS, 3.98 pH, 23.01% total sugars, 5.02% reducing sugars, and 0.211% acidity (Sahu et al., 2006). In this way, the whey with originally low sensory acceptability will get added to a product with good or high sensory appeal and can serve the consumer with good nutrition and improved health. Due to the high popularity of mangoes, mango pulp could also be added (2%, 4%, 6%, 8%, and 10%) to prepare different types of mango beverages and dry mixes to use whey concentrates and whey powders (Chavan et al., 2015). Fruit and milk-based beverages incorporating whey are receiving increased amounts of attention due to their delicious taste and high nutritional value. Pomegranate juice is very nutritious but comparatively more expensive than other fruit juices. Therefore, researchers have developed chakka (acid) whey beverage by incorporating 15% pomegranate juice with 10% sugar. The flavor of pomegranate juice improved the sensory score (8.65) of the developed beverage (Babar et al., 2008). A whey-based watermelon beverage can also be developed by blending watermelon juice (15%) and sugar (7%), along with different concentrations of betel leaf distillate (0%, 1%, 2% and 3%) into channa whey (75-78%). The beverage exhibited a desirable red color, highly acceptable taste, and overall acceptability (Naik et al., 2009), which helped improved the flavor of the beverage, thus enabling the utilization of whey.

Whey is termed as nectar from milk and is used to make a variety of diverse and value-added food products, such as functional foods and nutraceuticals, for health-conscious consumers (Arora and Jha, 2005). While different variants of non-alcoholic, fruit-based whey beverages could be manufactured at commercial levels such as dietetic beverages, drinks with hydrolyzed lactose, milk-like drinks and powder drinks could be developed using various flavoring agents like chocolate, coca, vanilla, cereals (mostly rice, oat and barley), and honey. Fermented whey beverages could also be developed with various probiotics such as Lactobacillus rhamnosus, Lactobacilus acidophilus, Lactobacillus delbrueckii sbsp. bulgaricus, Streptococcus thremophillus, Lactobacillus rhamnosus and Bifidobacterium animalis, Lactobacillus casei

for improved nutritive value, enhanced gut health benefits and sensory properties (Jeličić et al., 2008). Thus, whey valorization into ready-to-serve drinks can make positive contributions in ameliorating the problems of poor access to potable water, malnutrition, and pollution of aquatic ecosystems.

Since livestock rearing for milk and meat production creates an impact on the environment, the buying market for plant-based alternatives is growing. To safeguard the health of consumers such plant-based alternatives need a regulatory framework (Arora, 2025). Utilizing whey in vegetable products such as soup can serve not only as an excellent low-cost bulking agent but also help to get it into the space for plant-based healthy products. It will also help overcome vitamin B2 (riboflavin) deficiency, such as has been reported among vegans and those who consume little milk in developing countries where there is a risk of riboflavin insufficiency (National Institute of Health, 2022), among others. The signs and symptoms of riboflavin deficiency (also known as ariboflavinosis) include skin disorders, hyperemia (excess blood) and edema of the mouth and throat, angular stomatitis (lesions at the corners of the mouth), cheilosis (swollen, cracked lips), hair loss, reproductive problems, sore throat, itchy and red eyes, and degeneration of the liver and nervous system (Said and Ross, 2014).

The possibilities of utilizing whey and fruits/vegetables for preparation of soups have been explored by many researchers. Kamat et al., (1999) valorized paneer whey for the preparation of a nutritious and delicious soup by blending it with 25% tomato pulp and 20% beet root pulp. Not all fruit ingredients were liked by the tasting panel. For example, kokum fruit syrup was reported to have poor utility in the preparation of soup from paneer whey. Shelf-stable tomato whey soup was also obtained by Singh (2001) using 67.65% cheese whey, 30% tomato pulp, 1.25% corn flour, 0.4% sugar, 0.7% seasonings, 1% salt and permitted food colors (sunset yellow FCF 40 ppm and raspberry red 50 ppm) at pH 4.8. In-pouch sterilization of tomato soups (F0 value of 2.96, 1110C for 30 min) required a total processing time of 85 min. The sterilized tomato whey soup remained acceptable for up to 60 days of storage at 300C with overall acceptability of 7.4 score on a 9-point hedonic scale. Consumer response studies indicated that 61% of consumers liked the soup very much and the soup was liked moderately by 24% of consumers.

A chicken–whey soup was prepared by utilizing heads from slaughtered spent hens and paneer whey (0, 10, 15 and 20% levels) along with spice mix, condiments, thickening agent, common salt and monosodium glutamate. The mixture was cooked at 15 psi pressure (1210C) for 30 min and filtered to get the soup. The level of the added heads significantly (P<0.01) affected the contents of fat, protein, consistency, and overall palatability and significantly (P<0.05) influenced meat flavor intensity (MFI). Addition of 20% chicken heads to whey is recommended for making a good quality chicken-whey-soup as the product scored highest for flavor, consistency, MFI and overall acceptability and contained the highest concentrations of fat, protein, ash and total solids among all the products (Chindanandaiah and Sanyal, 2001).

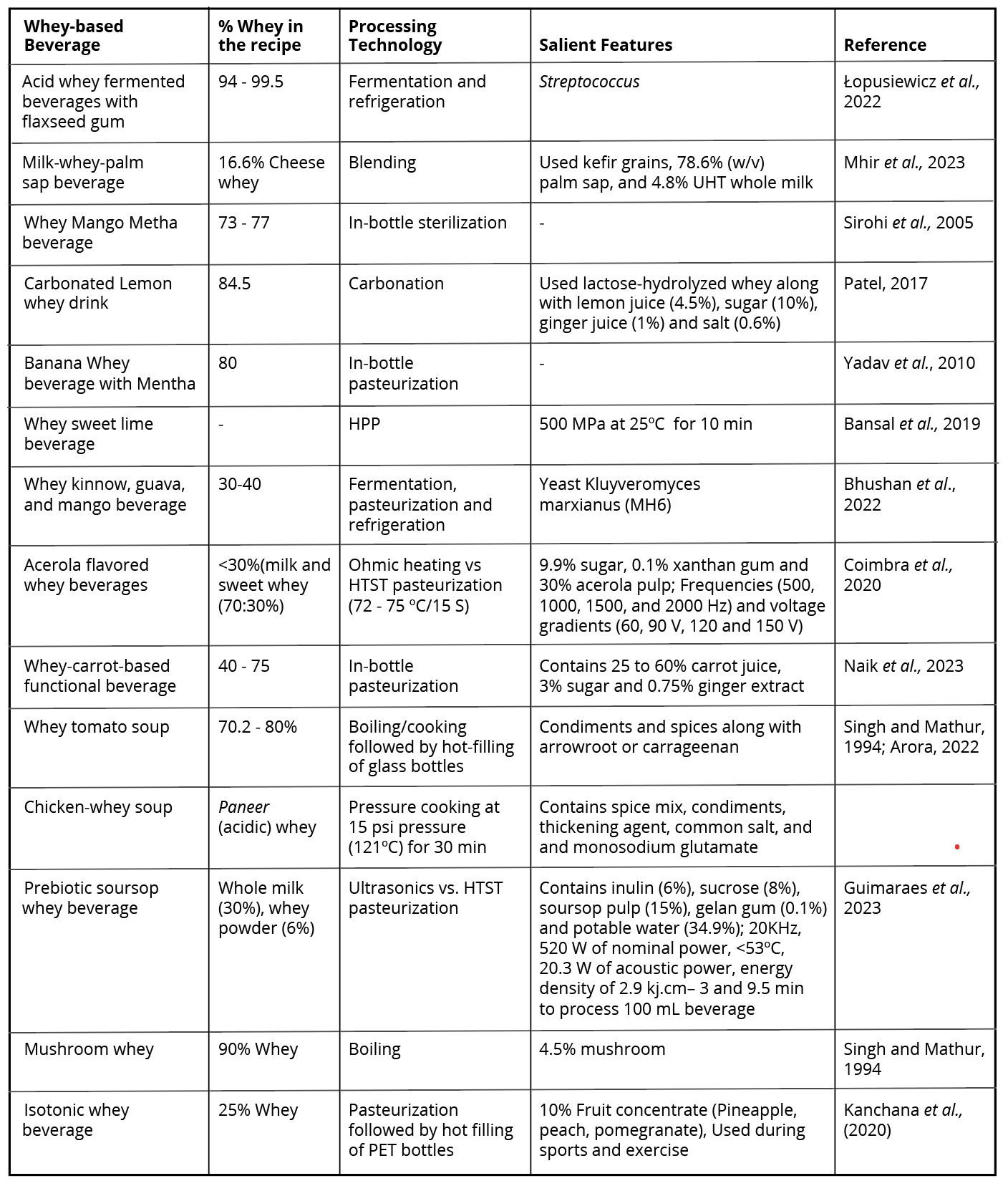

As evident from Table 2, the reuse of whey into beverages, including fermented and aerated products, or soups, involves simple processes and technologies similar to those used with fluid milk (Finnegan et al., 2017) which is known to use less energy (0.32 kWh kg-1 for processing of raw milk into packaged pasteurized milk). It allows 100% of the milk (including whey) to be used with equipment already available in an artisanal factory (Santos et al., 2023). Therefore, it is understood that the utilization of whey into beverage or soup making will not have much impact on generating greenhouse effect and thereby help in reducing the burden of global warming. The nutrients in whey used in such beverages will also help improve the health of consumers, thereby reducing food security. In fact, this approach of valorizing whey from waste into delicious drinkable products can help generate revenue, if performed with proper planning and execution. And thus, it will fit into the suggested triple bottom integrated model of sustainability based on environment, social and economic impact.

Nutritional and Therapeutic Value

A vast and growing literature is devoted to the “nutritional value concept” of whey. Whey is separated from the curd after the coagulation of milk or milk products. In India, coagulation can be achieved through the action of suitable enzymes of non-animal origin or by acidification and heating (FSSR, 2011). The primary ingredients in both sweet and acid whey after water are lactose (70 -72% of the total solids), whey proteins (8-10%), and minerals (12-15%) (Macwan et al., 2016). Whey is a source of calcium, phosphorus, and other salts/electrolytes (Table 3). Hence, whey has been utilized for the manufacture of isotonic sports drinks with the incorporation of simple sugars and sodium in the right amount (Kanchana et al., 2020).

The nutritional benefits of whey also come from the water-soluble vitamins that are transferred from milk into whey, such as 40-70% of vitamin B12; 55-75% of vitamin B6 and pantothenic acid; 70-80% of riboflavin and biotin; and 80-90% of thiamine, nicotinic acid, folic acid, and ascorbic acid (Bohora, 2018). Whey proteins consist of immunoglobulins, serum albumin, beta-lactalbumin, beta-lactoglobulin, and protease peptones (Farrell et al., 2004). With the absence of dietary fiber, and anti-nutritional factors such as phytates and oxalates, whey proteins are easy to digest and have high true protein digestibility (100%) (Singh and Arora, 2023; Arora, 2023). The quality of protein may also be described in terms of the protein efficiency ratio (PER), net protein utilization (NPU) and biological value (BV). Whey contains all essential amino acids in high concentrations and shows higher absorption and assimilation by the body than proteins sourced from wheat, corn and soy (Beseduik et al., 2024); therefore, the quality of whey protein is also very high in terms of PER (3.2), NPU (92), and BV (104) (Arora, 2023). The presence of all these ingredients in whey makes it a highly nutritious product (Narayanan, 2013). Whey protein is often referred to as a “fast protein” due to its ability to quickly provide nourishment to muscles and support muscle building. Therefore, there is a trend to use it as an essential part of the diet of people active in sports, athletes, body builders, and gym enthusiasts.

In addition to benefiting people suffering from malnutrition, whey protein plays various physiological roles and has the potential as a functional food component for individuals with obesity and related conditions, such as hypertension, type II diabetes, and hyper- and dyslipidemia (Macwan et al., 2016). It exhibits an anti-obesity effect by enhancing thermogenesis and preserving lean muscle mass (Wright et al., 2022). Whey protein is potentially protective against cancer and heart disease and assists in enhancing immune defenses (Kim et al., 2023; Ha et al., 2021). Thus, individuals who are obese, suffering from cardiovascular disease and those who wish to improve their health may realize benefits from consuming whey-based products.

Whey protein fractions, including lactoferrin, glycomacropeptide, and alpha-lactalbumin, offer additional health benefits. Lactoferrin aids in iron absorption and helps prevent pathogens from attaching to the intestinal wall, making it important for the nutritional health of infants and children. Lactoferrin-iron-binding properties reduce the risk of colon cancer (Ramani et al., 2024). Whey beverages containing lactoferrin may also improve calcium absorption, which is beneficial to those dealing with osteoporosis (Miller, 2005). Whey exhibits potent antioxidant activity primarily through cysteine-rich proteins that contribute to the synthesis of glutathione, a powerful intracellular antioxidant with potential anti-aging properties. Antioxidant components may also protect against aging-related alterations as these might alleviate oxidative stress involved in damaging sperm macromolecules during the aging process (Kandil et al., 2022). Other components, such as glutathione peroxidase and beta-lactalbumin, provide detoxifying and iron-chelating properties, reducing oxidative stress by minimizing the production of reactive oxygen species and protecting against heavy metals (Corrochano et al., 2019). Immunoglobulins and lysozyme present in whey offer immune-enhancing benefits, while antihypertensive peptides derived from bovine beta-lactoglobulin have been shown to reduce blood pressure. Whey proteins are a rich source of branched-chain amino acids (BCAAs), such as isoleucine, leucine, and valine. The BCAAs are metabolized directly into muscle tissue and are essential for exercise and resistance training (Sherwood et al., 2007). The BCAAs, especially leucine, play a crucial role in tissue growth and repair (Brestenskỳ et al., 2021).

Whey also contains lactic acid and insoluble nitrogen and has been used for the treatment of various diseases, such as jaundice, infected skin lesions, arthritis, anemia, liver complaints, HIV infection, and for its antioxidative action, anticarcinogenic activity (Corrochano et al., 2019; Darade and Ghodake, 2012). Minerals such as potassium, magnesium, calcium and selenium play important roles in nerve transmission, muscle contraction, blood pressure regulation, and bone health. It also contains enzymes such as lactoperoxidase that inhibit the growth of bacteria and fungi. Additionally, whey provides essential vitamins such as A, B1, B2, B3, B5, B6, C, D, and E (Onwulata and Huth, 2008). Generally, the pasteurization process is considered safe for milk and other liquid food products (Yadav et al., 2023). Fuliaş et al., (2014), reported that vitamins B1, B2, and B6 had relatively high thermal stability and vitamin B2 was the most stable vitamin (Herrera-Ardila et al., 2022). Thus, the nutrients present in whey can supplement the diet of those who suffer from micronutrient or protein deficiency disorders.

Recent Developments in Whey Valorization Toward Sustainable Goals

The valorization of whey is increasingly an urgent global focus in both food technology and wastewater management. Currently, products such as exopolysaccharides, bioactive peptides, single-cell (microbial) oils, bacteriocins, various enzymes and organic acids can be manufactured utilizing precise fermentation technology for ingredient manufacturing from whey (Gutierrez-Hernandez et al., 2022, Hausjell et al., 2019; Chourasia et al., 2022). To reduce the cost of production and the global warming potential of whey processing, application of the steam infusion technique for the heat treatment of whey for the manufacturing of various products has also been suggested (Brooks et al., 2021). Also, an improved redox-mediated electrodialysis system was suggested by Kim et al., (2022), which can result in high recoveries of salts (99%) and whey proteins (>98%) while decreasing energy consumption and operating costs.

The 6th Sustainable Development Goal (SDG 6) seeks to ensure the availability and sustainable management of water and sanitation for all, focusing on drinking water and sanitation. The conversion of whey into beverages, with or without fermentation, is an attractive approach toward its utilization for human consumption while simultaneously offering a sustainable solution to conserve scarce freshwater resources. To maintain the nutritional, biological, and functional characteristics of whey beverages to support, for example, the quality of fermented whey beverages, the application of non-thermal pasteurization processes has been advocated (Thisari et al., 2023). Among non-thermal techniques, ultrasounds have been found to improve the solubility of whey proteins, thereby reducing the formation of sediments in the whey beverage (Režek-Jambrak et al., 2008). Also, the simple technique of acidification of whey to pH < 3.9 can be employed to make whey proteins thermoresistant, which do not cause precipitation, even during UHT sterilization treatments (Jelen, 2003).

Conclusion

Whey contains a significant amount of water, water-soluble vitamins, lactose, proteins, and minerals. If unused, it creates a burden on the environment, when it could, instead, supply water and nutrients in the form of beverages and soups. Dairy herds consume a great deal of global freshwater, produce milk, and much of the substantial water component is then discarded as whey. When whey could be re-employed in potable beverages, it would address the worry of environmentalists, and others, about the water footprint associated with milk and milk product production. The cost (economic and environmental) and the complexity of processing waste whey streams means that its discharge into wastewater must cease. Indeed, wastewater containing whey is among the most serious environmental problems globally, due to the massive volume produced per annum across the world. Furthermore, whey treated as effluent is a wasted resource in the global context of dwindling clean and safe drinking water. However, whey should be regarded as a valuable resource having various applications as a nutritious and functional ingredient that offers potential health benefits, including support for muscle growth. Therefore, one must avoid emerging non-food uses, and instead, it should be transformed into diverse and delicious beverages, providing a low-cost and nutritious natural alternative for quenching thirst for various segments of underprivileged and malnourished populations. Whey-based beverages use various fruit components and additives, resulting in diverse formulations. Manufacturing flavored whey beverages is a feasible, easy and economical approach that food processors should consider for making profits and providing nutrition (both as valuable nutrients present as solids and as the water portion of whey) to consumers. The utilization of whey in various drinks has the potential to offer sustainable and viable solutions for whey disposal management. It would help to realize dairy products diversification and simultaneously offer nutritious options for health-conscious consumers, as well as those in need.

• Ethics approval and consent to participate: Not Required

• Consent for publication: Yes, both authors have given the consent.

• Availability of data and material: Not applicable

• Competing interests: None

• Funding: No funding received

• Authors’ contributions: Both authors contributed equally towards the conception and preparation of the MS.

References

Arora SK (2022). Process Optimization for Whey-Based Tomato Soup. Act Sci Nutr Health 6 (2): 133-139.

Arora SK (2023). An Overview of Importance and Nutritional Evaluation of Food Protein Quality. Act Sci Nutr Health 7(7): 96-101.

Arora SK (2023). Does Mix of Plant-based Dietary Fibres Affect Milk Protein True Digestibility?: An in-vivo Study. Int J Dairy Technol 76(4): 844-850.

Arora SK (2025). The Unregulated Plant-based ‘Milk’ Industry: A Threat to Nutrition, Health and Safety? Int J Dairy Technol78: e13117.

Arora SK, Jha YK (2005). Whey- the nectar from milk. Beverage and Food World, 32(8): 43-45.

AWS (Alliance for Water Stewardship) (2020). Case Study: Implementing the AWS Standard. Nestlé Sheikhupura, Pakistan South Asia. AWS. https://a4ws.org/download/implementing-the-aws-standard-nestle-sheikhupura-pakistan/.

Aydiner C, Sen U, Topcu S, Sesli D, Ekinci D, Altınay A, Ozbey Unal B, Koseoglu Imer D, Keskinler B (2013). Techno-economic investigation of water recovery and whey powder production from whey using UF/RO and FO/RO integrated membrane systems. Desal Water Treat 52: 1-11.

Babar RB, Salunkhe DD, Chavan KD and Thakare VM (2008). Utilization of pomegranate juice for the preparation of chakka whey beverage. J Dairy Foods Home Sci 27(2): 87-93.

Bansal V, Jabeen K, Rao PS, Prasad P, Yadav SK (2019). Effect of high-pressure processing (HPP) on microbial safety, physicochemical properties, and bioactive compounds of whey-based sweet lime (whey-lime) beverage. J Food Meas Charact 13(1): 454-465.

Besediuk V, Yatskov M, Korchyk N, Kucherova A, Maletskyi,Z (2024) Whey – From waste to a valuable resource, J Agr Food Res 18: https://doi.org/10.1016/j.jafr.2024.101280.

Bhushan K, Kocher G, Jindal P (2022). Valorisation of whey for fermented beverage production using functional starter yeast. Acta Alimen 51(3): 313-324.

Bohora G (2018). Preparation of whey-based pineapple beverage and its storage quality evaluation. Thesis, Doctor of Philosophy, Tribhuvan University, Kirtipur, Nepal. 9 p.

Bordenave JS, Almeida B, Piot J M, Sannier F (2005). Effect of protein concentration, pH, lactose content and pasteurization on thermal gelation of acid caprine whey protein concentrates. J Dairy Res, 72(1): 34-38.

Borkar MA, Zinjarde RM, Chore NS, Prajapati AM (2020). Preparation of chakka whey beverage blended with watermelon (Citrullus lanatus) Juice. J Pharmacogn Phytochem 9(6): 1280-1283.

Boulay AM, Drastig K, Amanullah A, Charlon V, Civit B, DeCamillis C, De Souza M, Hess T, Hoekstra AY, Ibidhi R, Lathuilliere MJ, Manzardo A, McAllister T, Morales RA, Motoshita M, Palhares J, Pirlo G, Ridoutt B, Russo V, Salmoral G, Singh R, Vanham, D, Wiedemann S, Zheng W, Pfister S (2021). Building consensus on water use assessment of livestock production systems and supply chains: Outcome and recommendations from the FAO LEAP Partnership. Ecol Indic124: 107391.

Brestenskỳ M, Nitrayová S, Patráš P, Heger J, Nitray J (2021). Branched chain amino acids and their importance in nutrition. JMBFS: 197-202.

Brooks C, Swainson M, Beauchamp I, Campelos I, Ishak R, Martindale W (2021). Transformational steam infusion processing for resilient and sustainable food manufacturing businesses. Foods 10: 1763.

Buchanan D, Martindale W, Romeih E, Hebishy E (2023). Recent advances in whey processing and valorisation: Technological and environmental perspectives. Int J Dairy Technol 76: 1-22.

Chavan RS, Nalawade T, Kumar A (2015). Studies on the development of whey-based mango beverage. Food Dairy Technol 3(2):1-6.

Chindanandaiah, Sanyal MK (2001). Physico-chemical and sensory quality of chicken-whey soup prepared from spent hen heads and whey. Beverage and Food World 28(9): pp. 18-20.

Chourasia R, Phukon LC, Abedin MM, Padhi S, Singh SP, Rai AK (2022). Whey valorization by microbial and enzymatic bioprocesses for the production of nutraceuticals and value-added products. Bioresour Technol Rep 19: 101144.

Coimbra LO, Vidal VAS, Silva R, Rocha RS, Guimaraes JT, Balthazar CF, Pimentel TC, Silva MC, Granato D, Freitas MQ, Pollonio MAR, Esmerino EA, Cruz AG (2020). Are ohmic heating-treated whey dairy beverages an innovation? Insights of the Q methodology. Lebensmittel-Wissenschaft & Technologie 134: 110052.

Corrochano AR, Saricay Y, Arranz E, Kelly PM, Buckin V, Giblin L (2019), Comparison of antioxidant activities of bovine whey proteins before and after stimulated gastrointestinal digestion. Int J of Dairy Sci 102 (1): 54-67.

Cruz-Salomón A, Ríos-Valdovinos E, Pola-Albores F, Lagunas-Rivera, S, Meza-Gordillo R, Ruíz-Valdiviezo VM, Cruz-Salomón KC (2019). Expanded granular sludge bed bioreactor in wastewater treatment. Glob J Environ Sci Manag 5: 119-138.

Darade RV, Ghodake SS (2012). An overview of whey beverages. Res J Anim Husb Dairy Sci 3(1): 41-44.

Devi LS, Chandra R, Singh D (2017). Study on sensory quality evaluation of whey-based fruit juice beverages. Pharm Innov J 6(9): 310-314.

Divya, Archana K (2009). Effect of different temperatures, timings and storage periods on the physicochemical and nutritional characteristics of whey-guava beverage. World J Dairy Food Sci 4: 118-122.

Djuric M, Caric M, Milanovic S, Tekic M, Panic M (2004). Development of whey-based beverages. Eur Food Res Technol 219: 321-328.

Dooley JJ (2014). Bounding the marginal cost of producing potable water including the use of seawater desalinization as a backstop potable water production technology. U.S. Department of Energy. Pacific Northwest National Laboratory, Washington. Microsoft Word – desal and fresh water costs for GCAM March 20 2014.docx (pnnl.gov) Accessed 06.12.2023.

EFSA (2010). Panel on Dietic Products, Nutrition, and Allergies (NDA) Scientific opinion on dietary reference values for water. EFSA J 8:1459-1507

Farkye NY (2017). Quark, quark-like products, and concentrated yogurts. In Cheese: Chemistry, Physics and Microbiology (4th edn). Cambridge, UK: Elsevier Academic Press. Pp. 1103-1110.

Farrell Jr HM, Jimenez-Flores R, Bleck GT, Brown EM, Butler JE, Creamer LK, Hicks CL, Hollar CM, Ng-Kwai-Hang KF, Swaisgood HE (2004). Nomenclature of the proteins of cows’ milk-sixth revision. J Dairy Sci 87(6): 1641-1674.

Finnegan W, Goggins J, Clifford E, Zhan X (2017). Global warming potential associated with dairy products in the Republic of Ireland. J Clean Prod 163: 262-273.

FSSR (2011). Food Safety and Standards (Food Products Standards and Food Additives) Regulation, 2011. Food Safety and Standards Authority of India. MoHFW, New Delhi. www.fssai.gov.in. Accessed on 22 May 2023.

Fuliaş A, Vlase G, Vlase T, Oneţiu D, Doca N, Ledeţi I (2014). Thermal degradation of B-group vitamins: B1, B2 and B6: kinetic study. J Therm Anal Calorim 118(2): 1033-1038.

Gosalvitr P, Cuellar-Franca RM, Smith R, Azapagic A (2019). Energy demand and carbon footprint of cheddar cheese with energy recovery from cheese whey. Energy Procedia 161:10-16.

Gosalvitr P, Cuellar-Franca RM, Smith R, Azapagic A (2021). Integrating process modelling and sustainability assessment to improve the environmental and economic sustainability in the cheese industry. Sustainable Production and Consumption 28: 969-986.

Gutierrez-Hernandez CA, Hernandez-Almanza A, Hernandez-Beltran JU, Balagurusamy N, Hernandez-Teran F (2022). Cheese whey valorization to obtain single-cell oils of industrial interest: An overview. Food Biosci 50 (A): 102086.

Ha DJ, Kim J, Kim S, Go GW, Whang KY (2021). Dietary Whey Protein Supplementation Increases Immunoglobulin G Production by Affecting Helper T Cell Populations after Antigen Exposure. Foods 10.

Hausjell J, Miltner M, Herzig C (2019). Valorization of cheese whey as substrate and inducer for recombinant protein production in E. coli HMS174 (DE3). Bioresour Technol Rep 8: 100340

He C, Liu Z, Wu J, Pan X, Fang Z, Li J, Bryan BA (2021). Future global urban water scarcity and potential solutions. Nat Commun 12: doi.org/10.1038/s41467-021-25026-3.

Cooley H, Purisamban R, Gleick P (2019). The cost of alternative urban water supply and efficiency options. California Environ Res Commun 1: 042001

Hebishy E, Yerlikaya O, Mahony J, Akpinar A, Saygili D (2023). Microbiological aspects and challenges of whey powders – I thermoduric, thermophilic and spore-forming bacteria. Int J Dairy Technol 76: 779-800.

Herrera-Ardila YM, Orrego D, Bejarano-López AF and Klotz-Ceberio B (2022). Effect of heat treatment on vitamin content during the manufacture of food products at industrial scale. DYNA 89(223): 127-132.

Higham C, Horne D, Singh R, Kuhn-Sherlock, B, Scarsbrook MR (2017). Temporal and spatial water use on irrigated and non-irrigated pasture-based dairy farms. J Dairy Sci 100: 6772-6784.

Holsinger VH, Posati LP, Devilbiss ED (1974). Whey Beverages: A review, J Dairy Sci 57 (8): pp. 849-859.

Huffman LM, de Barros Ferreira L (2011). Whey-based ingredients. Dairy Ingredients for Food Processing 1: 179-198.

Ingale MP, Ranveer RC, Nagargoje KD (2009). Development of whey-based custard apple beverage. Beverage & Food World 36(5):143-144.

Jelen P (2022). Utilization and products. Whey processing. Ency Dairy Sci 1:731-738.

Jeličić I, Božanić R, Tratnik L (2008). Whey-based beverages-a new generation of dairy products. Mljekarstvo 58:257-74.

Jungbluth N, Chudacoff M, Dauriat A (2007). Life cycle inventories of bioenergy. Final report ecoinvent data 2:17.

Kamat RP, Toro VA, Joshi SV, Burte RG, Dandekar VS (1999). Whey utilization for the manufacture of soup. Indian J. Dairy Sci. 52 (6): 396-398.

Kanchana N, Deepa S, Veeranan AGV, Saravana P, Vijayalakshmi R (2020). Studies on standardization of whey based isotonic sports beverages. Int J Food Sci and Nut 5(5): 28-33.

Kanchana N, Vijayalakshmi R (2021). Development and Evaluation of Whey-based Herbal Beverages as Health Drink. Madras Agric J 108(1): 79-85.

Kim HS, Park SC, Kim HJ, Lee DY (2023). Inhibition of DAMP actions in the tumoral microenvironment using lactoferrin-glycyrrhizin conjugate for glioblastoma therapy. Biomater Res 27 (1): 52.

Kim N, Jeon J, Elbert J, Kim C, Su X (2022). Redox-medi-ated electrochemical desalination for waste valorization in dairy production. Chem Engin J 428: 131082.

Kuhlman T, Farrington J (2010). What is Sustainability? Sustainability 2(11):3436-3448.

Łopusiewicz Ł, Dmytrow I, Mituniewicz-Małek A, Kwiatkowski P, Kowalczyk E, Sienkiewicz M, Drozłowska E (2022). Natural gum from flaxseed by-product as a potential stabilizing and thickening agent for acid whey fermented beverages. App Sci 12(20): Article 10281.

Lord J, Thomas A, Treat N, Forkin M, Bain R, Dulac P, Behroozi CH, Mamutov T, Fongheiser J, Kobilansky N, Washburn S, Truesdell C, Lee C and Schmaelzle PH (2021). Global potential for harvesting drinking water from air using solar energy. Nature 598(7882): 611-617.

Macwan SR, Dabhi BK, Parmar SC, Aparnathi KD (2016). Whey and its utilization. Int J Curr Microbiol Appl Sci 5(8): 134-155.

Mallik J, Kulkarni S (2010). Quality of rusks prepared by incorporation of concentrated whey. J Food Sci Technol 47: 339-342.

Mekonnen MM, Hoekstra AY (2012). A Global Assessment of the Water Footprint of Farm Animal Products. Ecosystems 15: 401-415.

Mhir S, Ziadi M, Mejri A, Ayed I (2023). Mixture of whey-milk and palm sap for novel kefir beverage using simplex-centroid mixture design. Kuwait Journal of Science 50(4): 690-696.

Miller G (2005). Healthy growth ahead for wellness drinks. Food Technol 59: 2-10.

Naik B, Kohli D, Walter N, Gupta AK (2023). Whey-carrot based functional beverage: Development and storage study, Journal of King Saud University – Science, 35(6): 102775

Naik YK, Khare A, Choudhary PL, Goel BK, Shrivastava, A (2009). Studies on Physico-chemical and Sensory Characteristics of Whey Based Watermelon Beverage. Asian J Research Chem 2: 57-59

Narayanan R (2013). Health augmenting properties of whey. Int J Curr Microbiol Appl Sci 2: 152-154.

National Institute of Health (2022). Riboflavin – Health Professional Fact Sheet

Kandil N, Sabry D, Ashry N, El-Sayyad H (2022). Studies on the anti-aging properties of bovine whey supplementation on reproductive hormonal profiles and sperm structure and function of adult and senile rats, Food Bioscience 45: 101369.

Oliveira DFD, Granato D, Barana AC (2017). Development and optimization of a mixed beverage made of whey and water-soluble soybean extract flavored with chocolate using a simplex-centroid design. Food Sci Technol 38: 413-420.

Onwulata CI, Huth J (2008). Whey Processing, Functionality and Health Benefits. A John Wiley & Sons, Ltd., Publication, Ames, USA. pp 1-13.

Patel R (2017). Technology for carbonated lemon whey beverage. Research & Reviews: J Food and Dairy Tech 5(2): 30-37.

Patel S, Prasanth PL, Chaudhari PL and Sahu C (2007). Techno-Economic Feasibility of Whey Based Mango-Herbal (Ginger) Beverage. Ind J Dairy Sci 60: 149-155.

Perasiriyan V, Chandrakala S, Sivakumar T (2013). Whey based herbal drink evaluation as health supplement. Int J Food Agric Vet Sci 3(2): 58-62.

Ramani A, Hazra T, Mudgil S, Mudgil, D (2024). Emerging potential of whey proteins in prevention of cancer. Food and Humanity 2: 100199, https://doi.org/10.1016/j.foohum.2023.12.007

Rodell M, Famiglietti JS, Wiese DN, Reager JT, Beaudoing HK, Landerer FW, Lo MH (2018). Emerging trends in global freshwater availability. Nature 557: 651-659.

Ryan KN, Vardhanabhuti B, Jaramillo DP, van Zanten JH, Coupland JN, Foegeding EA (2012). Stability and mechanism of whey protein soluble aggregates thermally treated with salts. Food Hydrocoll 27:411-420

Sahu C, Patel S, Choudhary PL (2006). Technology for manufacture of whey-based mango-herbal (lemongrass) beverage. J Food Sci Tech 42(5): 421-424.

Said HM, Ross AC (2014). Riboflavin. In: Ross AC, Caballero B, Cousins RJ, Tucker KL, Ziegler TR, eds. Modern Nutrition in Health and Disease. 11th ed. Baltimore, MD: Lippincott Williams & Wilkins, pp. 325-30.

Sherwood S, Jenkins D, Rittmanic S (2007). Protein beverage and method of making same. US Patent Application No. 11/859,715. Publ, 1: 1-18.

Singh GP, Mathur MD (1973). Channa whey-its composition. Ind J Dairy Sci 26(3): pp. 201-203.

Singh J, Arora SK (2023). Antinutritional Factors in Plant Based Foods – A Review. Int J Agric Sci 19(1) 366-375.

Singh SK (2001). Shelf stable tomato whey soup. Indian Dairy Man 53(3): 62.

Sirohi, Sahu C, Patel S, Choudhary PL (2005). Studies on preparation and storage of whey-based mango herbal (Pudina) beverage. J Food Sci and Technol 42: 157-161.

Smithers GW (2008). Whey and whey proteins-From ‘gutter-to-gold’. Int Dairy J 18(7): 695-704.

Srinivasan MR, Ananta Krishnan JP (1965). Milk products of India. ICAR, Pub. New Delhi.

Thisari AB, Srimali PM, Charitha JG (2023). Fermented whey beverages: A review of process fundamentals, recent developments and nutritional potential, Int J Dairy Technol 76(4): 737-757.

Tunick MH (2008) Whey protein production and utilization: a brief history. In: Whey processing, functionality and health benefits. John Wiley & Sons, New Jersey, USA. pp 1-13.

United Nations World Water Development Report 2023: Partnerships and Cooperation for Water. UNESCO, Paris.

Vörösmarty CJ (2010). Global threats to human water security and river biodiversity. Nature 467: 555-561

Vyas SH, Pandya AJ (1981). Utilization of byproducts from dairy industry. Indian Dairyman 33(3): 115-522.

Wang W, Shi Y, Zhang C, Hong S, Shi L, Chang J, Li R, Jin Y, Ong C, Zhuo S, Wang P (2019). Simultaneous production of fresh water and electricity via multistage solar photovoltaic membrane distillation. Nat Commun 10 (1): Article 3012.

Whittleir EO, Webb BH (1970). By products from milk. Reinhold Publishing Corp, New York.

WHO/UNICEF (2011). Drinking Water Equity, Safety and Sustainability: JMP Thematic report on drinking water.

WHO/UNICEF (World Health Organization/United Nations Children’s Fund) (2021). Progress on Household Drinking Water, Sanitation and Hygiene 2000-2020: Five Years into the SDGs. Geneva, WHO/UNICEF. www.who.int/publications/i/item/9789240030848. Licence: CC BY-NC-SA 3.0 IGO.

Wright CS, Hill ER, PC Reyes Fernandez, Thompson WR, Gallant MA, Campbell WW, Main RP (2022). Effects of dietary protein source and quantity on bone morphology and body composition following a high-protein weight-loss diet in a rat model for postmenopausal obesity. Nutrients 14 (11): 2262.

WWAP (UNESCO World Water Assessment Programme) (2017). The United Nations World Water Development Report 2017. Wastewater: The Untapped Resource. Paris, UNESCO. https://unesdoc.unesco.org/ark:/48223/pf0000247153.

Yadav RB, Yadav BS, Kalia N (2010). Development and storage studies on whey-based banana herbal (Mentha arvensis) beverage. Am J Food Technol 5(2): 121-129.

Yadav S, Arora SK, Vats S (2023). Vitamins and Minerals: A review on processing losses and strategies to control it. Modern Concepts & Developments in Agronomy 12(2): 1178-1182.

Discussion with Reviewers

Reviewer: Why are people not using whey when there are so many recipes for new products that have been standardized and reported in the literature?

Answer: To our knowledge, there is no known research study done to specifically determine the reason that whey is going to waste. The one reason quoted frequently is “the scattered production of small quantities of whey” in small/cottage units manufacturing paneer/channa/chakka.

However, there are four main factors that influence how whey is used, which we will discuss below.

First, the manufacturing of paneer/channa/chakka mainly focuses on the profits to be made from the sale of these products; thus, the manufacturer may not have either the intention or the facilities needed to produce other whey products, such as beverages or soups.

The decision to utilize whey should come largely from those managing organizations producing and handling whey.

Secondly, there is no pressure to use whey exerted on manufacturers by environmentalists, governing bodies or law framing authorities to use whey diligently and avoid wasting it by pouring it down drains.

Third, whey is the largest portion (in bulk) of the main product of interest. Since it is bulky, large tanks/silos are required to store it. These silos should preferably be insulated for storage of the chilled whey.

Fourth, since whey is highly perishable, it should be stored under proper refrigeration and may also require some processing, such as through pasteurization along with neutralization just after its collection; this treatment may be costly and require the investment of time, labor, and resources at the plant where it is being produced.

Last, but not least, the basic underlying reason for the underutilization of whey may be that both small-scale as well as large-scale manufacturers may not realize the importance of whey in terms of nutrients and its potable water content. As a result, there is reluctance to use whey on a commercial scale.

Reviewer: Do you think the bulkiness of whey and its storage needs may be a factor that interferes with manufacturers using it further?

Answer: Yes, it could be a reason, as cited above. Since the storage capacity of a plant is limited and they need to handle fresh supplies of milk to prepare dairy products (for the next batch/shift), the bulkiness of whey may keep the storage tanks occupied and may pose some problems. Hence, manufacturers would need to make dedicated investments in beverage/soup processing units where the stored whey can be used and efficiently stored.

Reviewer: Why do you call whey a nectar from milk? (from your previous paper, Arora SK, Jha YK (2005). Whey- the nectar from milk. Beverage and food world 32(8): 43-45)

Answer: Just as juices/nectar are extracted from fruits/flowers, we perceive whey as an extracted liquid from milk after coagulation and removal of curd. Further, as the fruit juices and nectars carry the healthful and nutritious elements of fruits and flowers with them, so it is with whey. Therefore, we describe whey as nectar from milk.

Reviewer: Please share more details about generating awareness of using whey as a source to replace drinking water during the preparation of various products.

Answer: As researchers, we can generate awareness by publishing articles on the health and climate benefits and positive impacts of the use of whey as a source for replacing drinking water (fully or partially) during the preparation of beverages, soups, and other products; this can be done through international journals, as well as local newspapers, periodicals and bulletins. We should also conduct seminars/workshops and training programs showing methods for processing whey for its proper storage as well as its incorporation into various products, without affecting quality. Further research work revealing the health benefits of whey may be undertaken to strengthen manufacturing and consumer confidence in the many ways that whey can be used.