SPECIAL EDITION

New Devices

Solar Concentrator-Powered Atmospheric Water Condensation System: Extracting Water From Humidity While Providing a “Clean Slate” for Beneficial Water Structuring

H Jabs* and B Rubik

Institute for Frontier Science, 6114 LaSalle Ave PMB 605, Oakland, CA 94611, USA

*Correspondence: harry@frontiersciences.org

Keywords: atmospheric water condenser, ammonia absorption refrigeration, solar concentrator, water memory, structured water, water remineralization.

Received: October 2, 2021

Revised: December 18, 2021

Accepted: December 21, 2021

Published: April 25, 2022

Abstract

One of the most challenging effects of climate change is lack of safe drinking water in more and more areas of the world. Wells are expensive and may contain toxins or give rise to legal hurdles. Conventional atmospheric water condensers are technically feasible but cost-prohibitive because of fuel or electricity consumption. A solar collector combined with an ammonia absorption refrigeration system is a perfect match where low-grade heat energy is efficiently collected from sunlight and used to drive a cooling cycle to condense ambient humidity while providing refrigeration and room cooling.

The condensate is essentially distilled water free of toxins commonly present in ground and surface sources. It is “virgin” from a structured water perspective sourced in situ from completely unstructured individual H2O vapor molecules and can therefore be considered nascent before any structuring has begun. Any previous “memory of water” would have been erased. This offers the unique opportunity to remineralize the water with selected beneficial mineral beds and use energizing flow patterns to revitalize it, and possibly imbue it with information if desired.

While solar concentrators and absorption refrigeration are not new technologies, the innovations are efficient transfer of heat from the concentrator to the refrigerator, automation, optimal system control with an inexpensive microcontroller and the low-cost/low-tech/low-maintenance design of the system. Currently there are no such systems on the market. Non-technical personnel can be taught to build, program, and maintain an installation. Since it is self-contained and self-sufficient, it is mobile if mounted on a trailer for rapid deployment to areas of need.

Introduction

An adequate supply of safe drinking water has become an ever more urgent problem as populations have grown and climate change has created droughts of increasing severity in many areas of the world (Huang et al., 2021). A solar-powered water condensation system can readily meet the most urgent water needs of a community and aid in achieving the 17 Global Sustainability Goals of the United Nations (Cf, O.D.D.S., 2015).

The most severe water shortages occur in subtropical and tropical regions of the world (Rosa et al., 2020). These same regions typically have intense sunshine, which lends itself perfectly for efficient heat generation with solar collectors (Web ref. 7). When this heat is applied to an ammonia absorption refrigeration cycle then water can be condensed from atmospheric humidity and simultaneous refrigeration and air cooling provides food safety and comfort. The harvested water is of high quality which can be even further increased in value through beneficial remineralization, revitalization, and structuring.

Solar collectors and ammonia absorption refrigeration are both mature technologies that are low-tech and can be fabricated from readily available base materials by moderately skilled tradesmen. The combining of these two established technologies has so far eluded the markets because of design shortcomings and manufacturing costs (Lima et al., 2021). The design shortcomings are overcome with an efficient heat transfer scheme from the solar collector focus to the hot side of the ammonia absorption refrigerator. Additionally, electronic sensing and control fully automates the system and runs it optimally under all operating conditions. This optimization maximizes the benefit-cost ratio and minimizes physical size through high efficiency. Manufacturing costs are minimized by using under-utilized resources in the predominantly poverty-stricken populations in need of such atmospheric water condensers. Unemployed persons can be taught the trade skills to fabricate, assemble, program, and maintain such a system. Initially, volunteers and low-wage workers can be recruited locally to serve their community with this critical infrastructure. As trade skills and manufacturing sites are developed, business development is encouraged to expand regionally.

There is a positive social impact to the community as individuals contribute meaningfully to society while providing for their families. Unemployment is reduced, while dignity, self-worth and pride return. As poverty is reduced and trade skills are increased, a positive feedback loop is established to further the United Nations Sustainability Goals.

Theoretical Feasibility

The system can roughly be modeled as having inputs of warm humid air along with solar radiance and outputs of cold liquid water with cool dry air. To estimate the theoretical capacity of such a solar-powered atmospheric water condenser, it is instructive to calculate the water content present in air humidity and the gross energy flux received from the sun.

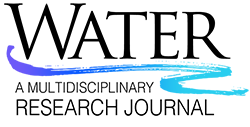

The schematic shown in Figure 1 illustrates air flowing across a small lot carrying water vapor for potential condensation. Assuming conservative estimates of light wind averaging 1 m/s wind speed (Beaufort wind scale) and a 60 m2 capture cross-section (30 m property width by 2 m capture height), an air column of 86400 m length (1 m/s times 86400 sec) traverses the lot daily. This volume of 5184000 m3 (60 m2 cross-section by 86400 m column length), assuming 40% relative humidity at 20°C (1 m3 air contains 7 ml water according to the psychometric chart), carries a staggering 36288 L of water within it!

Figure 1. Estimate of water contents in atmospheric humidity.

With respect to energy, the most applicable parameter to characterize a solar concentrator is the direct normal irradiance. It measures the total solar energy received at the Earth’s surface on an area perpendicular to the incident sun rays but having the atmospheric losses due to absorption and scattering subtracted. Since the energy flux is location-dependent, the arid and semi-arid regions of the subtropics shall serve as a realistic use case where an atmospheric water condenser might be needed. Solar resource maps indicate daily energy levels of 5 – 6 kWh/m2 per day. With conservative 5 kWh/m2 the theoretical energy flux impinging on a 600 m2 lot amounts to 3000kWh daily.

The theoretical estimates illustrate the vast amount of water and energy present on a small lot, even in arid or semi-arid regions of the Earth. For a realistic and practical system, a parabolic solar collector of 3 m diameter is assumed. It provides a surface area of 7 m2 exposed to an energy flux of 35 kWh daily collected mainly in the form of heat. This energy is used to first cool the ambient air from the assumed 20°C to its dew point at 6°C and then extract the water’s latent heat of vaporization to form a condensate. At 100% theoretical conversion efficiency 250 L of water can be extracted daily. Realistically, if a 10% system efficiency is achieved, then 25 L water per day can be extracted fuel-less from the atmosphere. During operation a cooling capacity equivalent to a 1-ton air conditioning unit, or 12000 BTU/h, is provided as an additional benefit.

Condenser Methods

Existing Atmospheric Condensers

There are three main techniques to extract water from ambient air humidity; condensation on a cold surface, trapping water in hygroscopic desiccant, and pressurizing the air. All methods require large amounts of energy because of the very high latent heat of vaporization of water. The phase transition of water from vapor to liquid requires the removal of 2260 kJ/kg energy. If this energy must be provided in the form of electricity or fuel, the operation often becomes impractical because of an exorbitant cost or lack of infrastructure (no electrical grid or fuel availability). With regard to renewable energies, photovoltaic and wind energy have high initial costs, leaving only solar heat generation as a realistic energy form. Even though heat is the lowest grade of energy it is a lucky coincidence that this system happens to require exactly this form of energy to operate!

The following list describes existing atmospheric water extraction technologies and their characteristics.

Dehumidifier condensers. A heat exchanger is cooled below the dew point such that humidity in passing air is condensed. The cooling is typically achieved through vapor compression of a refrigerant, which requires a mechanical compressor that uses electricity or fuel to operate.

Peltier condensers. A semi-conducting material is used to produce the Peltier effect, where a hot and a cold side are created when current is passed through p-n junctions. This process is relatively inefficient requiring large amounts of electricity and does not easily scale up.

Fog fence. Water droplets in fog collect on large sections of vertical canvas and then flow down into a collection trough. This technique is very effective and efficient in the presence of fog but ceases when the sun vaporizes the fog by daybreak. It captures only liquid water, not water vapor.

Absorption in dry desiccants. Solid desiccants like silica gel or zeolite absorb moisture from the air. When they are saturated then they must be regenerated to extract the water and ready them for the next cycle. This is a batch process and requires substantial energy.

Absorption in wet desiccants. A wet desiccant, such as salt in concentrated brine solution, absorbs ambient humidity. However, as with all desiccants, when saturated it must be regenerated, which requires substantial amounts of energy.

Metal-organic framework (MOF) absorbers. A new and intriguing water harvesting technique using solar energy has recently been announced (Furukawa et al., 2014; https://doi.org/10.1021/ja500330a) (Kim et al., 2017; https://doi.org/10.1126/science.aam8743). This new class of metal-organic framework materials can be engineered for specific properties. Researchers at the University of California, Berkeley, produced crystalline powder that has a strong affinity to incorporate water molecules into its atomic matrix. A prototype was built that regenerates the material with solar heat. Unfortunately, the MOF raw materials are still too expensive for practical applications at scale.

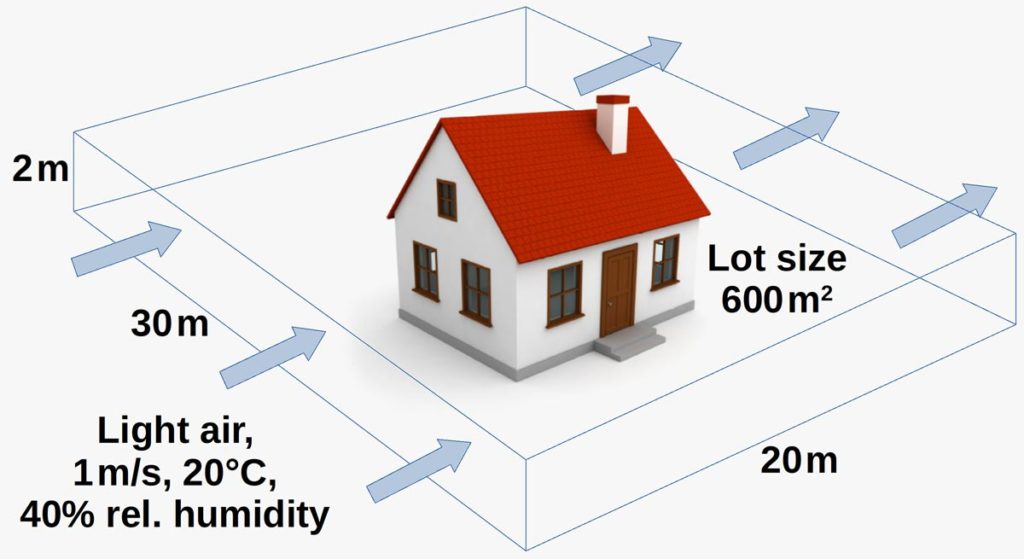

A summary of the features of these condensers is compiled in Table 1 and compared to the solar concentrator-driven condenser.

Table 1: Comparison of atmospheric water condensers.

Table 1: Comparison of atmospheric water condensers.

Technical Approach

The system leverages two well-developed existing technologies, solar-concentrators and absorption refrigerators, and combines them in a practical and scalable way. They are practical, because lay persons can be trained to install, maintain, and even build such systems from mainly base materials. They are also scalable, because both technologies are highly scalable from small trailer-mounted emergency units through residential to industrial or communal installations. Systems may be operated in parallel to scale capacity. Use of the inexpensive Arduino® microcontroller (Web ref. 1) enables operation with optimal efficiency under varying conditions. Because high efficiency is always maintained, the system produces the most product (water, refrigeration or air cooling) under all operating conditions for a given installation size. The system is designed to be modular such that the solar concentrator, the absorption refrigerator or the heat transfer assembly may be used independently or together. For example, existing absorption refrigerators (typically large industrial systems) can be retrofitted to supplement the required heat from solar concentrators and therefore save fuel and reduce operating costs and carbon footprint. The condensate is a high-quality water source that can be further enhanced with beneficial minerals and water structurizers.

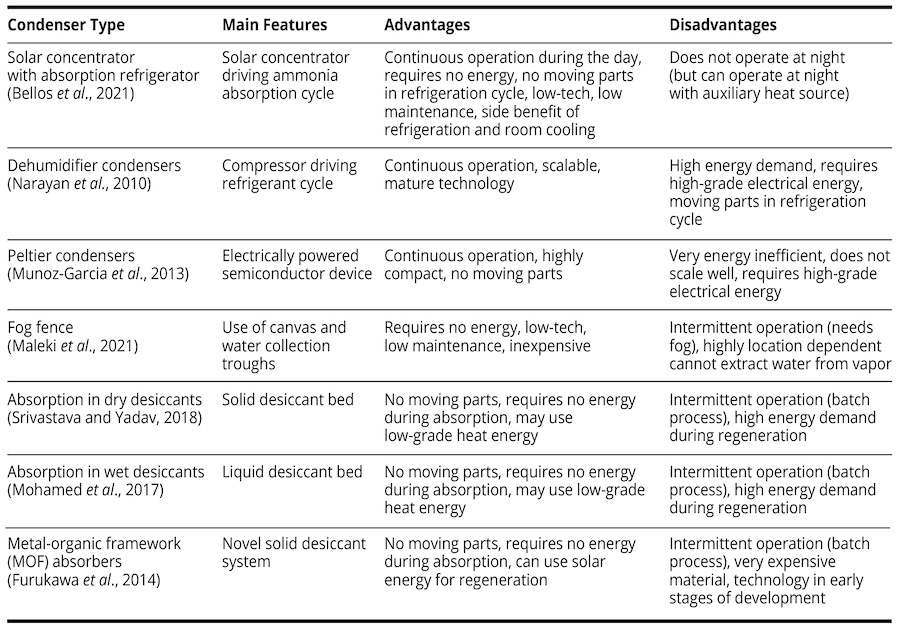

Figure 2. Schematic of solar concentrator-powered water condenser with refrigeration and room cooling. Basic system shown without condensate remineralizer, structurizer or auxiliary solar panels.

The schematic of a basic condenser is shown in Figure 2. Heat generated in the parabolic concentrator is applied to the absorption refrigerator where it drives the cooling cycle. Ambient air is passed through the evaporator where humidity is condensed and water collected. A pump fills a pressure tank from which the product water is dispensed. A diverter valve in the air handler directs cold air into a room or to ambient, depending on cooling needs. For an entirely off-grid system a small photovoltaic panel may be added to provide electrical power to operate fans, pumps, and electronic components.

Technical Objectives

The development of a prototype is essential because it provides real-world data beyond theoretical models and reveals engineering challenges, or opportunities, that might not have been apparent during the design stage. The technical objective is to efficiently combine the two well-known technologies of solar concentrators and absorption refrigerators. A key engineering feature is the safe and efficient transfer of heat energy from the solar furnace to the boiler of the ammonia absorption refrigerator. Fabrication feasibility is assured by use of commonly available materials and technologies.

The research question to be answered is what overall efficiency can be achieved, while the engineering effort informs how to best integrate the system components. Other objectives are to identify challenges and devise solutions. The feasibility of the concept will be assessed according to efficiency, operating safety, ease of construction, cost and maintenance.

Figure 3. Parabolic mesh dish with tracker.

Solar Concentrator

An in-depth analysis of a tracking parabolic solar reflector is provided by Prinsloo (2014). http://dx.doi.org/10.13140/RG.2.1.1130.3522.

As a practical example a conventional C/Ku-band mesh satellite antenna with 3 m diameter can be used to build a prototype. A suitable dish kit is offered by TEK2000 in Scarborough, Ontario, Canada as shown in Figure 3 (Web ref. 2). It includes an actuator capable of tracking an arc of 100º and is supplied with an electronic positioner and digital inclinometer.

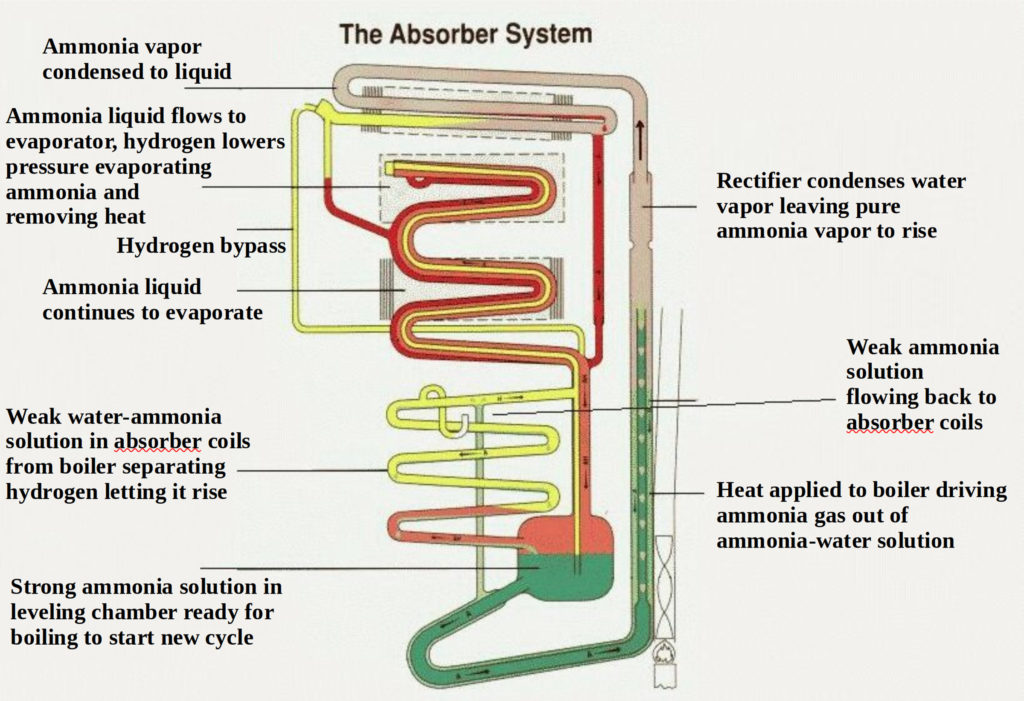

Figure 4. Schematic of an ammonia absorption cooling unit used in a typical motor home refrigerator. The cold cycle is driven by a heat source. There are no moving parts in the hermetically sealed system.

Absorption Refrigerator

The key opportunity of this atmospheric water condenser is that the low-grade heat energy efficiently collected by the solar concentrator happens to be exactly the energy form needed to operate an ammonia absorption refrigerator. A schematic of its working principle is shown in Figure 4. It does not have a compressor and there are no moving parts in the hermetically sealed piping system. The refrigeration cycle is based on the property of a water-ammonia mixture requiring heat energy to drive the ammonia out of solution. The gaseous ammonia is liquefied in the condenser and flows down to the evaporator where it extracts heat from its environment, whereby it produces the desired cooling effect. It subsequently reabsorbs in the water and the cycle repeats. While any heat source may be used to drive the cold cycle, solar-generated heat is preferred because it does not require any fuel. Waste heat or inexpensive heat from natural gas may be used to supplement system operation when solar energy is insufficient or not available during the night.

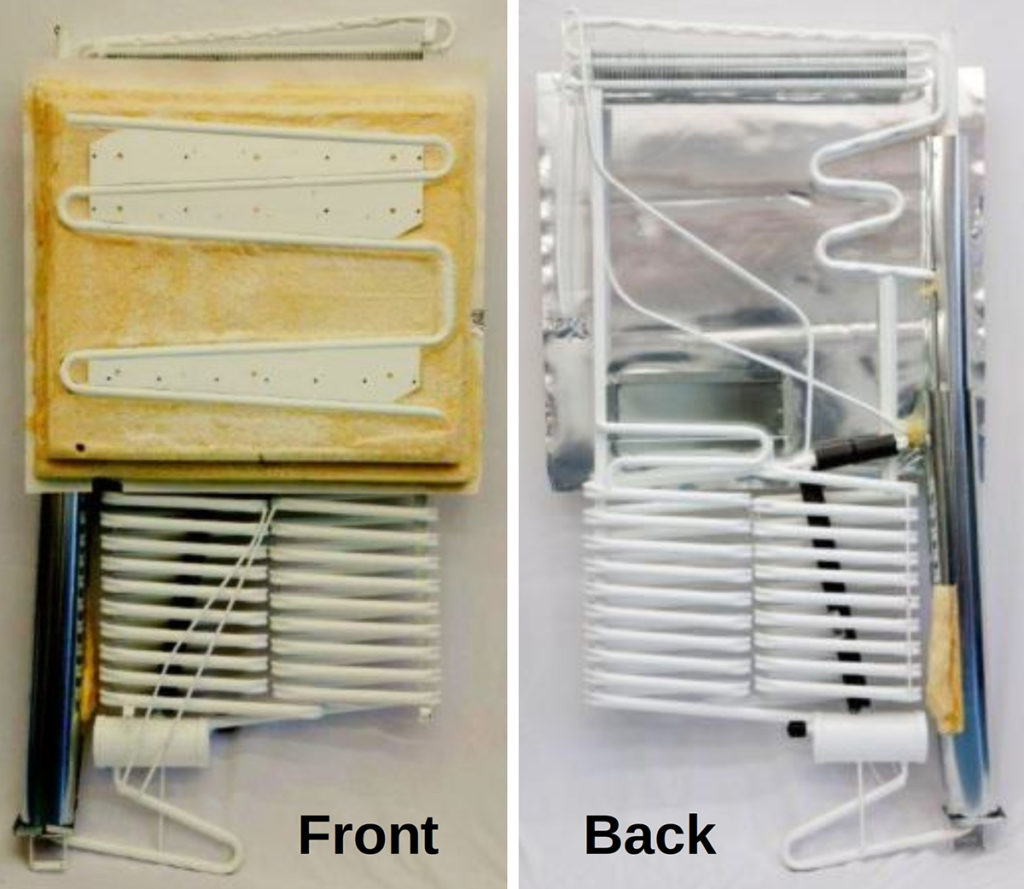

Figure 5. Replacement cooling unit for an absorption refrigerator as typically used in motor homes. Typical heat sources include 12VDC, 110/220 VAC or propane.

In a prototype application a replacement cooling unit for an absorption refrigerator can be used. These refrigerators are commonly installed in motor homes because they can be operated on propane when electricity is not available. A photograph of a suitable unit, the Norcold 1200LR, is shown in Figure 5 (Web ref. 3) depicting front and back sides. Heat is applied to the boiler at the bottom of the silver cylinder. While this heat is normally generated with an electrical heater or a gas flame, heat from the harvested solar energy will be applied instead. Soft copper tubing, as part of the heat transfer component, is wound tightly around the boiler tube facilitating good thermal contact that is enhanced with thermally conducting compound. Condensate water from the evaporator is collected in a pan or directed toward optional processing stages.

Heat Transfer

The solar radiation concentrated in the focal point of the parabolic dish is efficiently absorbed and converted to heat by a spiral-wound heat exchanger of approximately 12 cm diameter and 12 cm length, the solar furnace. It is formed from soft copper tubing and coated with heat-resistant matte black paint to absorb the maximum amount of solar energy.

The heat generated in the solar furnace must be transferred to the boiler of the refrigerator. This is accomplished with a working fluid and a recirculating pump. Water is an ideal heat transfer fluid because of its high heat capacity, which means that a volume can uptake and release large amounts of heat for a given temperature difference. Without phase transition from liquid to steam its working temperature is limited to 100ºC at atmospheric pressure, but it may be increased to 121ºC at 2 atm, 134ºC at 3 atm, 144ºC at 4 atm, and so on. For safety reasons it is desirable to keep the pressure and temperature as low as possible. Preliminary calculations indicate an optimal temperature/pressure well below 121ºC/1 atm, comparable to automotive engine cooling systems.

A conventional hot water recirculating pump, as used in residential radiator central heaters, can be used. A suitable model is the Grundfos UPS15-58FC with three selectable power levels of 60W, 80W and 87W for low, medium, and high flow speed, respectively (Web ref. 4). This pump is capable of a maximum flow of 64 L/min and a maximum head pressure of 6 m. All components of the heat transfer loop are thermally insulated with conventional foam insulation as used in residential HVAC (heating, ventilation, and air conditioning) applications. To accommodate the tracking motion of the parabolic dish, flexible hoses are used for the recirculating loop. Silicone rubber hoses with a 2.5 cm smooth inner diameter can be installed to handle the temperature and pressure and provide flow with minimal back pressure to maximize flow efficiency.

System Programming

There are many components in this solar-powered system that must operate together efficiently at varying energy input and demand output conditions. The inexpensive, yet powerful Arduino® microcontroller platform (Web ref. 1) is an open-source computer hardware and software project with a vibrant worldwide user community. After its inception in 2003, it quickly gained great popularity in the maker community (Wolf-Powers et al., 2017. https://doi.org/10.1080/01944363.2017.1360787) and for prototyping because of its easy-to-use hardware and easy-to-learn software.

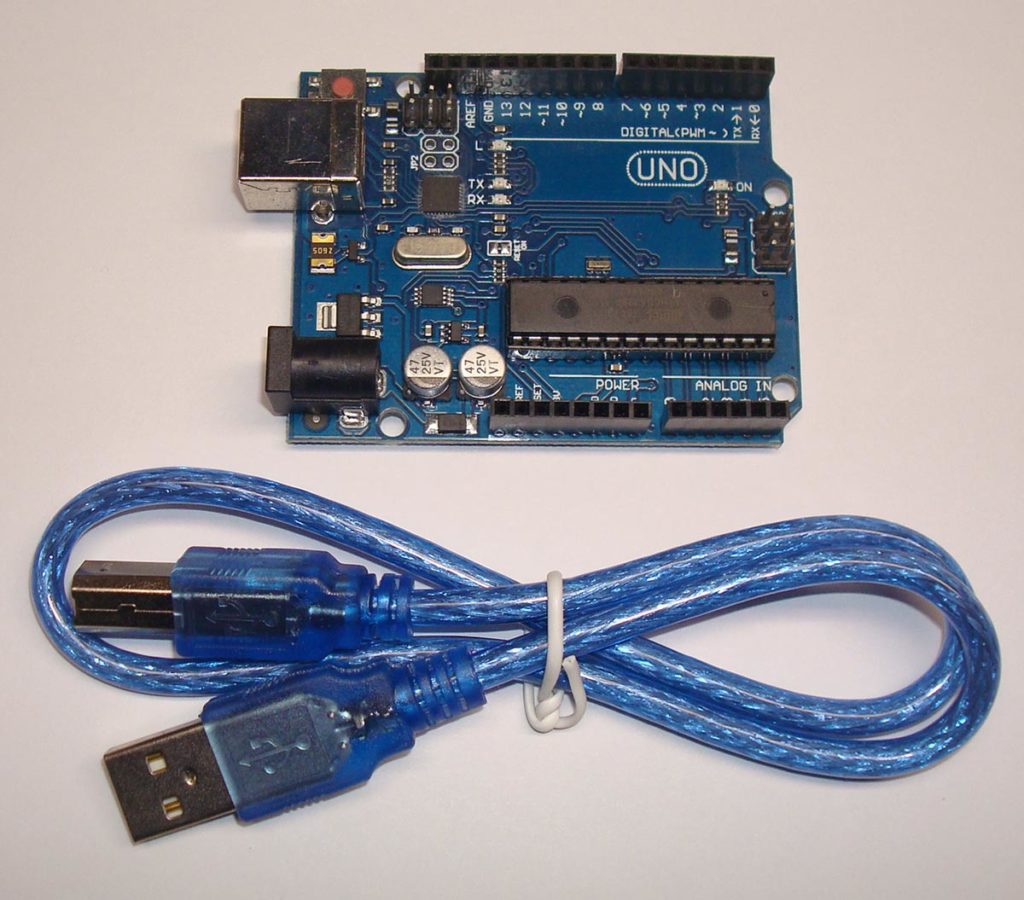

Figure 6. Popular low-cost Arduino® Uno microcontroller board with USB cable.

The Arduino® Uno, a popular controller board of this platform is shown in Figure 6 with convenient headers for many input/output and power connections. A prototyping board, called “shield,” may be stacked onto the main controller board making electrical and mechanical connections through the headers. This format allows for convenient and custom circuitry in a compact and clutter-free way to expand functionality. One such board is sufficient for stand-alone control of the entire condenser prototype processing sensor inputs, controlling actuators and optionally connecting to a PC computer for programming or transmitting data for display, analysis, and storage. If the computer is connected to the internet then remote access is possible from anywhere. The “Uno” is based on the Atmel ATmega328P 8-bit microcontroller chip (Web ref. 5) with 32 kB in-system programmable, non-volatile flash memory. It has 14 digital input/output pins (of which 6 can be used as pulse-width modulation outputs), 6 analog inputs, a 16 MHz ceramic resonator for clock generation, a USB connection, a power jack, an In Circuit Serial Programming (ICSP) header, and a reset button.

Sensors strategically placed throughout the entire system monitor its operating parameters in real-time for processing in the “Uno” and optimally control actuators. Example parameters to be measured are temperature, pressure, humidity, solar intensity, dish elevation and azimuth angle, the power consumption of recirculating pump and fans, product water flow, and chemical properties. The parabolic dish tracker is interfaced to the microcontroller and programmed to track the sun. The control system is modular such that sensors and actuators may be added as needed.

The microcontroller is programmed with the Arduino® integrated development environment (IDE) in the special Arduino language, which is a variant of C++ and supports object-oriented programming. A graphical user interface (GUI) can be programmed on the PC computer with, for example, the Qt® cross-platform application framework. Qt® is a registered trademark of The Qt Company Ltd. and its subsidiaries (Web ref. 6). It is a comprehensive software package specifically designed to easily port to many operating systems, such as Windows, Macintosh macOS or Linux. The Arduino® and Qt® software used is Free and Open-Source Software (FOSS) and only public licenses are required.

System Optimization

The condenser should operate with optimal efficiency under all encountered operating conditions but must also have built-in fail-safe mechanisms in case of component overload. The adaptation of the system to varying input supply and output demand is achieved through closed-loop control and look-up tables. An example of a feedback loop is the sun tracker, which directs the collector dish optimally toward the sun to meet the highest demand but “detune” its alignment when energy input becomes excessive. An example of a look-up table would be a data file that contains the sun’s polar and azimuthal angle for a given location on Earth at a given date and time. Such a look-up table is important during system startup and during cloud cover when the sun’s rays are diffuse and its position in the sky cannot be determined accurately. In this case the system falls back to robust open-loop operation before locking on to the optimal closed-loop control again.

As part of the development process the prototype system serves as a pilot project where real-world data are acquired, and an accurate performance assessment is made. The multitude of sensors furnishes a plethora of data to fully characterize the system and its components under varying environmental and operating conditions in real-time. When the condenser is operated for an extended period of time, revealing trends can be gleaned from the collected data during changes in solar energy supply and demand for condensate water and refrigeration. These variations may be categorized as short-term during weather changes, mid-term during the diurnal cycle, and long-term seasonally. Specific locations with their unique micro-climates add additional variables. As data is collected, a parameter field is mapped with ever finer granularity and system characterization.

Condensate Methods

Remineralize Water

Water condensate from atmospheric humidity is essentially distilled water with very low mineral content. It is naturally free of toxic heavy metals often found in ground water, but it also lacks important minerals to support optimal health, such as potassium, calcium, magnesium and phosphorous, among many others. However, it tends to leach minerals from our body, so it should not be consumed in large quantities. As reverse osmosis water purification systems and desalination plants have proliferated to fight water-borne diseases, the World Health Organization has addressed the issue in a special report (Kozisek, 2005. https://www.who.int/water_sanitation_health/dwq/nutrientschap12.pdf).

Fortunately, condensate water is easily remineralized by simply allowing it to flow over a bed of rocks. Importantly, by selecting rocks high in minerals that are generally low in the local diet, drinking this enriched water can compensate for deficiencies and boost health. A simple total dissolved solids (TDS) sensor can monitor the mineral content of the remineralized water. By adjusting the dwell time through flow control a target TDS value can be maintained.

Analyze Water

The water extracted from ambient humidity is monitored and analyzed in real-time from the moment of condensation to dispensation at the point-of-use for full quantitative and qualitative characterization of product water and system performance. Quantitative monitoring includes volume flow while the water quality is analyzed for conductivity, total dissolved solids (TDS), pH, oxidative reductive potential (ORP), turbidity and “energetic” content.

“Energetic” characterization of water is an unconventional, yet scientific, testing method based on digital Kirlian photography called gas discharge visualization (GDV) (Korotkov and Krizhanovsky, 2004; Rubik, 2011). It generates a plasma glow discharge near a drop of water suspended from a syringe tip above a transparent electrode that is electrically energized with high voltage at high frequency. The size and other parameters of the discharge image, including intensity, entropy, and fractality are indicative of the energetic quality of the water.

Structured Water

In recent decades a new scientific discipline investigating the molecular structure of water has emerged. It is based on the observation that the polar water molecules form domain clusters of varying size and structure. This unique state of water may be categorized as a liquid crystal, which exhibits properties between those of conventional liquids and solid crystals. Gerald Pollack, a world-renowned researcher in this rapidly developing field, published a seminal book summarizing key discoveries (Pollack, 2013).

Drinking “energized” or structured water has been shown to improve human health and well-being. (Rubik, 2012). This can be understood by the findings that this kind of water can more easily permeate cell walls and membranes and thus facilitate better hydration, detoxification, and more efficient transport of nutrients and metabolites. As a result, cells can optimally perform their respective functions in animal and plant tissues alike.

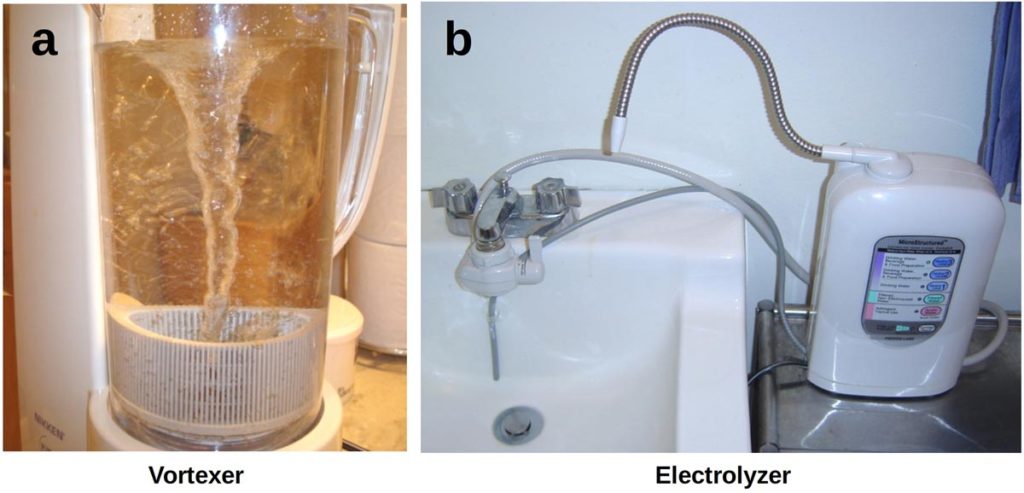

Figure 7. Two methods of energizing drinking water: a) vortexing through a field of strong permanent magnets and b) electrolyzing to add electrons and raise the pH of water collected from the cathode.

After the condensate has been mineralized, it can be subjected to a variety of so-called water energizing processes. These methods include vortexing, flowing past strong permanent magnets, and passing between electrolyzer plates to produce electron-rich alkaline drinking water, which has proven to be highly beneficial to human health (Giap and Muthuraman, 2020), (Magro et al, 2016), (Rubik, 2012). Two commercially available powered devices are shown in Figure 7. In addition, purported water structurizers that are passive and external, typically materials such as beverage coasters treated energetically by proprietary processes, are also commercially available. Water placed in contact with such a purported structurizer such as the Amezcua BioDisc-3 has been shown to acquire altered physical properties (Rubik, 2021; http://dx.doi.org/10.14294/WATER.2021.1), altered biological properties (Korotkov, 2019; http://dx.doi.org/10.15406/ijcam.2019.12.00468), and increased health benefits in drinking water (Korotkov et al., 2019; http://dx.doi.org/10.15406/jabb.2019.06.00190).

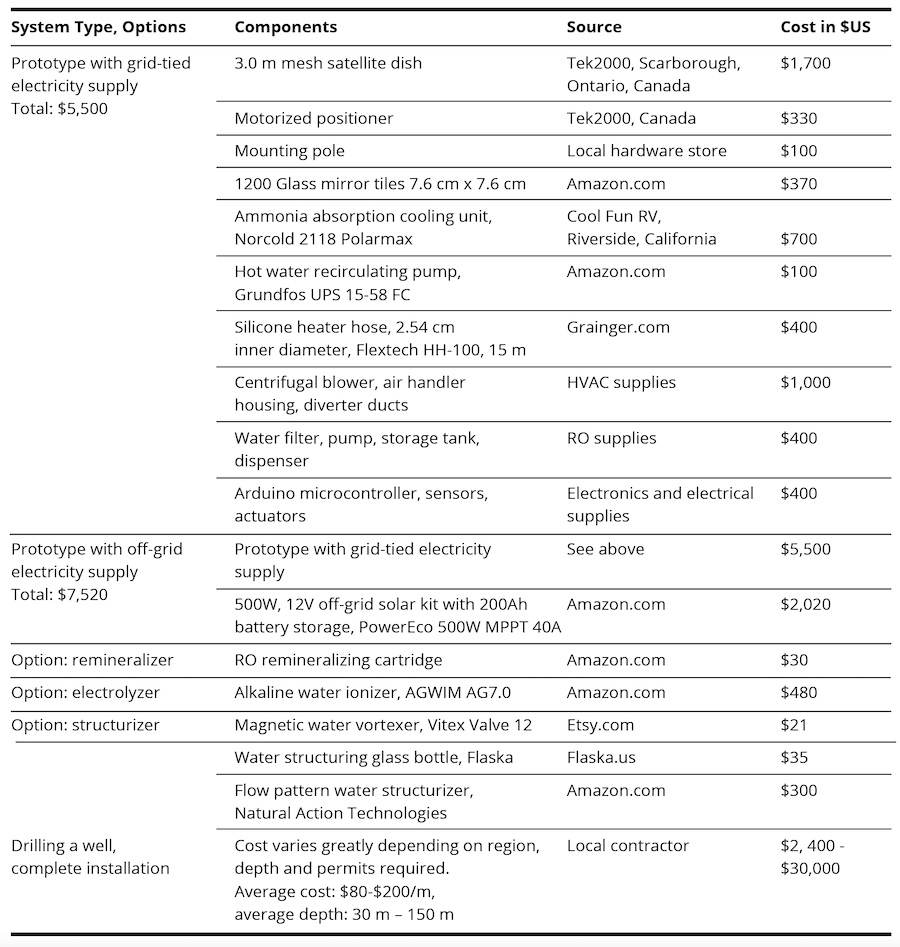

Table 2: Cost estimates of various system implementations.

Table 2: Cost estimates of various system implementations.

Cost Estimates

Costs vary greatly, depending on geographical location, local labor and material costs, system size and system type. To offer realistic examples, Table 2 lists itemized costs in US dollars, excluding labor, when sourced in the United States of America in 2021. The system is sized to produce approximately 25 L of drinking water and 1 ton of refrigeration per day using off-the-shelf components, some repurposed. Where labor costs are low, several components could be fabricated by tradesmen from inexpensive base materials, greatly reducing system expenses. The average cost range of drilling a well is included as a reference. However, it may be difficult to obtain a permit for a well; moreover, it cannot provide refrigeration but generally offers higher water flow rate.

Results

A feasible and practical design of a solar concentrator-powered atmospheric water condenser has been described. The system extracts highest-quality drinking water from ambient humidity while providing refrigeration and room cooling as a side benefit.

To model a realistic use case where such a system might be installed, environmental conditions prevalent in arid or semi-arid regions are assumed. The atmospheric water content passing over a small property was theoretically calculated. Assuming a capture cross-section of 30 m property width by 2 m capture height, a light air movement of 1 m/s and having 40 % relative humidity at 20°C carries over 36000 L of water with it daily. Solar power is used to condense a small fraction of this atmospheric “river.” The energy collected in a 3 m diameter parabolic solar concentrator is theoretically sufficient to condense 250 L daily or 25 L at a conservative estimate of 10% system efficiency. Simultaneous cooling capacity is equivalent to a 1-ton air conditioning installation.

To produce drinking water of superior quality, the condensate is remineralized and additionally “energized” for health benefits.

Discussion

The motivation to develop a practical solar-powered atmospheric water condenser is anchored in the increasing water shortages being experienced in many communities in arid and semi-arid regions. Often these very communities are stricken by poverty and high unemployment rates. Water wells are often cost-prohibitive, and drilling may be legally or geologically challenging. The condenser concept attempts to meet the community’s drinking water needs, bypass water rights by tapping into unregulated atmospheric water and avoid potentially contaminated ground or surface water sources. Designed as a low-tech system, it can be built locally by drawing on the available work force. As trade skills are taught in the fabrication process, entrepreneurial business development is encouraged to proliferate the technology, increase the education level, and improve the economy, first locally and then regionally.

The estimated amount of water present everywhere as atmospheric humidity is enormous. This water source is untapped, and freely available, but expensive to extract because it usually requires energy-intensive condensers. Harnessing solar power taps into another ubiquitous and freely available energy resource that is typically plentiful in drought-stricken locations. A solar concentrator-driven ammonia absorption refrigerator is most suitable for this niche application to meet the basic human need for clean drinking water. The side benefit of refrigeration reduces the risk of food-borne diseases and room cooling provides physical comfort.

From a systems point of view the input resources of atmospheric water and solar energy are plentiful. The amount of condensed water is therefore limited only by the physical size of the solar concentrator, the air handler, and the incorporated heat exchangers. Systems can be scaled up or operated in parallel.

Since solar concentrators and ammonia absorption refrigerators are mature technologies, the engineering challenge is focused on optimal system integration and efficient heat transfer from the solar furnace to the boiler of the refrigerator. Electronic automation and control are essential for high efficiency under greatly varying operating conditions and effective algorithms should be implemented.

Conclusion

A solar-powered atmospheric water condenser is technically feasible and can extract high quality drinking water without the supply of external energy. Because it can be fabricated locally, it has the potential to not only provide the “liquid of life” but also lift communities out of poverty and improve education and skills. Because it draws on resources freely available everywhere, it is not encumbered by legal hindrances, encouraging individuals and families to actively take control of and improve their circumstances. As part of the larger maker movement, it returns control of people’s lives to the local level through self-reliance, self-determination, and pride.

Discussion with Reviewers

We are grateful for the very constructive reviewer critique. We selected the following questions and provided these answers:

Reviewer: What are the cost estimates for implementing this project?

Authors: The paper was written as a guide to build a first prototype, mainly from off-the-shelf items, for a solid feasibility study and showcase of the system concept. We have added a “Cost Estimate” section to the manuscript, including a table listing recommended components and their current prices. The cost of drilling a well was also added as a reference.

Reviewer: What about equipment cost, such as the GDV?

Authors: We do not consider test equipment to be part of the prototype project. Such tests are optional and could be performed with rented equipment or outsourced to third party laboratories.

Reviewer: Would more references not be helpful?

Authors: Yes, certainly. More references were added according to the reviewer’s suggestions.

References

Bellos E, Chatzovoulos I, Tzivanidis C (2021). Yearly Investigation of a Solar-Driven Absorption Refrigeration System with Ammonia-Water Absorption Pair. Thermal Science and Engineering Progress, Vol. 23. Available online at: https://doi.org/10.1016/j.tsep.2021.100885.

Cf, O.D.D.S. (2015). Transforming Our World: the 2030 Agenda for Sustainable Development. United Nations: New York, NY, USA. Document available online at: https://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E

Furukawa H, Gándara F, Zhang YB, Jiang J, Queen WL, Hudson MR, Yaghi OM (2014). Water Adsorption in Porous Metal–Organic Frameworks and Related Materials. J. Am. Chem. Soc. 136(11): 4369–4381.

Giap LK, Muthuraman A (2020). Health Benefits of Alkaline Ionized Water. Rapports De Pharmacie 6(1): 616-621.

Huang Z, Yuan X, Liu X (2021). The Key Drivers for the Changes in Global Water Scarcity: Water Withdrawal Versus Water Availability. Journal of Hydrology 601: article 126658.

Kim H, Yang S, Rao SR, Narayanan S, Kapustin EA, Furukawa H, Umans AS, Yaghi OM, Wang EN (2017). Water Harvesting from Air with Metal-Organic Frameworks Powered by Natural Sunlight. Science 356(6336): 430-434.

Korotkov KG, Krizhanovsky EV (2004). The Dynamic of the Gas Discharge around Drops of Liquids. In book: Measuring Energy Fields: State of the Science. Backbone Publishing Company, Fair Lawn, USA: 103–123. Available online at: https://www.amazon.com/Measuring-Energy-Fields-State-Science/dp/097420191X

Korotkov K (2019). Study of Structured Water and its Biological Effects. International Journal of Complementary and Alternative Medicine 12(5): 168-172. Available online at: http://dx.doi.org/10.15406/ijcam.2019.12.00468

Korotkov KG, Churganov OA, Gavrilova EA, Belodedova MA, Korotkova AK (2019). Influence of drinking structured water to human psychophysiology. J Applied Biotechnol Bioeng 6(4): 171-177. Available online at: http://dx.doi.org/10.15406/jabb.2019.06.00190

Kozisek F (2005). Health risks from drinking demineralized water. World Health Organization, Nutrients in drinking water 1,1: 148-163. Available online at: https://www.who.int/water_sanitation_health/dwq/nutrientschap12.pdf

Lima, AAS, Leite, GdNP, Ochoa, AAV, dos Santos CAC, da Costa JAP, Michima PSA, Caldas AMA (2021). Absorption Refrigeration Systems Based on Ammonia as Refrigerant Using Different Absorbents: Review and Applications. Energies 14(48). Available online at: https://dx.doi.org/10.3390/en14010048

Magro M, Corain L, Ferro S, Baratella D, Bonaiuto E, Terzo M, Corraducci V, Salmaso L, Vianello F (2016). Alkaline Water and Longevity: A Murina Study. Evidence-Based Complementary and Alternative Medicine, Volume 2016, Article ID 3084126. Available online at: https://doi.org/10.1155/2016/3084126

Maleki M, Eslamian S, Hamouda B (2021). Principles and Applications of Atmospheric Water Harvesting. Chapter 16 in Handbook of Water Harvesting and Conservation: Basic Concepts and Fundamentals (New York Academy of Sciences) 1st Edition by Saeid Eslamian (Editor) and Faezeh Eslamian (Editor). ISBN-10: 978-1119478952, ISBN-13: 978-1119478959. Available online at: https://doi.org/10.1002/9781119478911.ch16

Mohamed MH, William GE, Fatouh M (2017). Solar Energy Utilization in Water Production From Humid Air. Solar Energy 148(15): 98-109. Available online at: https://doi.org/10.1016/j.solener.2017.03.066

Munoz-Garcia MA, Moreda GP, Raga-Arroyo MP, Marin-Gonzalex O (2021). Water Harvesting for Young Trees Using Peltier Modules Powered by Photovoltaic Solar Energy. Computers and Electronics in Agriculture, Vol. 93: 60-67. Available online at: https://doi.org/10.1016/j.compag.2013.01.014

Narayan GP, Sharqawy MH, Summers EK, Lienhard JH, Zubair SM, Antar MA (2010). The Potential of Solar-Driven Humidification–Dehumidification Desalination for Small-Scale Decentralized Water Production. Renewable and Sustainable Energy Reviews, 14(4): 1187-1201. Available online at: https://doi.org/10.1016/j.rser.2009.11.014.

Pollack GH (2013). The Fourth Phase of Water: Beyond Solid, Liquid and Vapor. Ebner & Sons Publishers, Seattle, Washington: 45-70. Available online at: https://www.amazon.com/Fourth-Phase-Water-Beyond-Liquid/dp/0962689548

Prinsloo GJ (2014). Automatic positioner and control system for a motorized parabolic solar reflector. M.Sc Engineering Thesis: 1-142. Stellenbosch University, Stellenbosch, Western Cape, ZA, Mechanical and Mechatronic Engineering. Available online at: http://dx.doi.org/10.13140/RG.2.1.1130.3522

Rosa L, Chiarelli DD, Rulli MC, Dell’Angelo J, D’Odorico (2020). Global Agricultural Economic Water Scarcity. Science Advances 6(18):1-10. Available online at: https://doi.org/10.1126/sciadv.aaz6031

Rubik B (2011). The Power of ‘Magnetized’ Water. Chapter 18 in: Bragdon E (editor). Spiritism and Mental Health. Philadelphia, PA: Jessica Kingsley Publishers, 201-211. Available online at: https://www.amazon.com/Spiritism-Mental-Health-Practices-Psychiatric/dp/1848191359/ref=sr_1_3?dchild=1&keywords=Spiritism+and+Mental+Health&qid=1633204177&s=books&sr=1-3

Rubik B (2012). Studies and Observations on the Health Effects of Drinking Electrolyzed-Reduced Alkaline Water. In: Pepper DW, Brebbia CA, and Laituri M (editors). Proceedings of Conference on Water and Society 2011. Wessex Institute of Technology, Southhamptom, UK. Available at: https://www.witpress.com/

Rubik B (2021). The Effects of Subtle External Stimuli on Chiral Symmetry Breaking During Crystallization of Sodium Chlorate from Aqueous Solutions. Water 12: 61-71.

Srivastava S, Yadav A (2018). Water Generation from Atmospheric Air by Using Composite Desiccant Material Through Fixed Focus Concentrating Solar Thermal Power. Solar Energy 169(15): 302-315. Available online at: https://doi.org/10.1016/j.solener.2018.03.089

Wolf-Powers L, Doussard M, Schrock G, Heying C, Eisenburger M, Marotta S (2017). The Maker Movement and Urban Economic Development. Journal of the American Planning Association 83, 4: 365-376.

Web References

Web ref. 1: https://store-usa.arduino.cc/collections/boards/products/arduino-uno-rev3 [09-27-2021]

Web ref. 2: http://www.tek2000.com/cgi-bin/web.cgi?command=product&item=300cm%20(10ft)%20C/Ku-Band%20Mesh%20Dish%20Starter%20Kit-ND [09-27-2021]

Web ref. 3: https://rvcoolingunit.com/1200-Norcold-Brand-New-Cooling-Unit-built-by-the-Amish-P13259.aspx [09-27-2021]

Web ref. 4: https://www.pexuniverse.com/grundfos-ups15-58fc-circulator-pump-59896341 [09-27-2021]

Web ref. 5: https://www.microchip.com/content/dam/mchp/documents/MCU08/ProductDocuments/DataSheets/Atmel-7810-Automotive-Microcontrollers-ATmega328P_Datasheet.pdf [09-27-2021]

Web ref. 6: https://www.qt.io/ [09-27-2021]

Web ref. 7: https://solargis.com/maps-and-gis-data/download/world